Site pages

Current course

Participants

General

MODULE 1. Introduction to production of agricultur...

MODULE 2. Advance in material for tractor and agri...

MODULE 3. Advanced manufacturing techniques

MODULE 4. Heat treatment of steel

MODULE 5. Industrial lay out planning and quality ...

MODULE 6. Economics of process

MODULE 7. Techno economic feasibility of project r...

MODULE 8. Servo motors, drives and controllers

MODULE 9. CNC controllers for machine tools

MODULE 10. CNC programming

MODULE 11. Assembly and plant automation storage a...

LESSON 2. MATERIAL USED FOR TRACTOR AND AGRICULTURAL MACHINERY

1.1 Introduction

The development in agricultural engineering has progressed extremely fast during the last decades. The most important milestones after the introduction of the diesel drive can be listed as follows:

-

combination of several process steps in one machine

-

oil hydraulic drives and controls

-

electronic controls

-

extreme increase in the performance of individual machines

All these obvious innovations easily lead us to oversee a comparatively inconspicuous, but very important development: The further development of the materials of parts and components used in modern agricultural machinery. Not all that long ago, a typical agricultural machine consisted exclusively of “iron and steel” as a rule.

This has changed considerably. The reasons for the use of different materials in modern agricultural machinery are:

higher load on the components due to increased machine performance

in parts, light-weight design is imperative on account of legal regulations and avoidance of soil compaction

increase of the resistance to wear due to higher loads on components and higher area capacities

increased demands on lifetime of modern agricultural machinery

increased demands on design and ergonomics of the machinery.

The progress in various materials will now be described as follows. Based on concrete examples of components taken from the range of KRONE products, modern materials and their properties will be described.

1.2 Material groups

In this chapter the following systematics will be followed:

1. Structural steels

2. Alloyed steels

3. Cast materials

4. Light alloys

5. Wearing materials

6. Synthetic materials

1.2.1 Structural steels

Structural steel is still the classic material for the load-bearing structures of our agricultural machinery. However, in the past the loads on these machine frames have increased as well as the necessity to reduce weight, which has several reasons. The high-performance modern machines are increasingly reaching the weight limits which are set by legal regulations. In Germany, for example, the weight on a driven axle is limited to 11.5 t. But also in smaller machines, such as a round baler, weight limits apply in Germany, such as an axle load of 3 t, as from which the use of an expensive brake system is obligatory.

In order to optimise the carrying capacity of the welded frames and their weight at the same time, KRONE has been using fine-grained structural steel in this field almost exclusively for many years. In this way it is possible to reduce the plate thickness and/or the profile cross section.

The strength of general structural steels can be increased by the addition of carbon. However, they can no longer be welded when a limit of 0.22 % of carbon is exceeded. Fine grained steels, however, retain an especially fine-grained structure even at a low content of carbon due to the special alloying constituents. Thus, they have a higher strength, but they can be welded very well and can also be cold shaped well.

1.2.2 Alloyed steels

Alloyed steels are used in the production of gears, thus for shafts and gear wheels. KRONE uses here very high-quality tempered steels in parts, such as 18CrNiMo 7-6 (#1.6587) and 42CrMo4V (#1.7225). Tensile strengths of up to 1200 N/mm² and hardness to be achieved of 62 HRC permit high loads on the components. High-quality materials enable the production of gear wheels and shafts with smaller dimensions, which along with the smaller gear housings lead to more constructive freedom and weight saving.

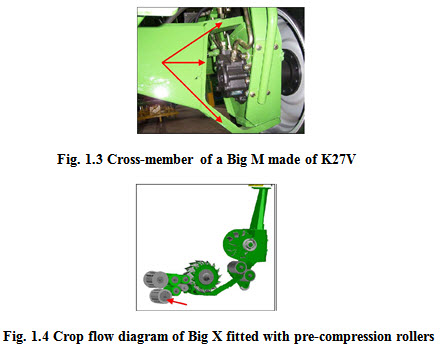

But for high-load welded components as well, KRONE uses a special material of this category with the designation K27V. This is a boron-alloyed steel which in a quenched state can be welded well up to a hardness of 50 HRC. Tensile strengths of up to 1100 N/mm² are achieved.

This material is used for the cross-member of the steering axle of the self-propelled mower-conditioner Big M, for example. This heavily loaded component consists of 90 x 40 mm flat steel which is welded to the rear-axle cross-member. In parts, non-corroding steels are also used. They are used wherever rust formation caused by aggressive media has to be prevented, but anti-corrosive coating has no space, however. Another property of this material is used for the Big X forage harvester: The front pre-compression rollers are made of X15CrNiSi2520 (#1.4841) because this material is not magnetisable.

The lower pre-compression roller contains a metal detector which has the task to recognise metal parts in the forage, immediately shutting down the feed system of the forage as protection of the blade drum. As this system is operated on the basis of an induction principle, a roller made of magnetisable steel would shield the sensor, thus making it ineffective.

1.2.3 Cast materials

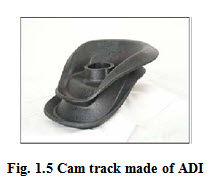

As they are the classic materials, flake-graphite cast iron (GG), nodular-graphite cast iron (GGG), malleable cast iron (GT) as well as cast steel (GS) are used. For some years now, KRONE has been using a new cast material, namely the so-called ADI cast, the abbreviation of which stands for "austempered ductile iron". ADI is produced by means of a multiple-stage heat treatment of ductile cast iron. Given certain tenacity, ADI offers double the strength of nodular-graphite cast iron. Moreover, ADI has good attenuation properties and a very good anti-wearing behavior. KRONE uses ADI as a material for cam tracks in rotary rakes.

The cam follower rollers of the tine arms run-in this cam track, which takes place under high surface pressure and very dusty conditions. On account of the properties of ADI described, this is possible without lubrication. The positive experience enables KRONE to give a three-year warranty on the wear of the cam track.

1.2.4 Light alloys

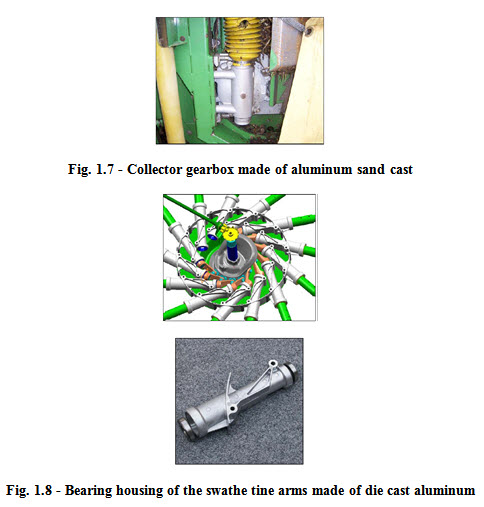

Light alloys are used mainly for parts made of aluminum alloys. They are used wherever weight reduction is crucial. The row-independent Easy Collect maize header of KRONE is an example to be mentioned here.

For harvesting maize, the Big X forage harvester is fitted with a front harvesting attachment, which can take up to fourteen rows of maize at the same time. In order to minimize the weight transfer of the rear axle of the forage harvester, it is necessary to keep the weight of the maize header as low as possible. The gear housings of the various drives used in the Easy Collect contribute to this end as they are cast from AlSi7MgO aluminum alloy. At a volume mass of 2.65 g/cm³ this alloy is 2/3 lighter than steel. All in all a weight of about 120 kg is saved for a twelve-row maize header. Another example for the use of aluminum alloys is fitted in the rotary rakes. The bearing housing is made of die cast AlSi10Mg.

The mass reduction of 34 kg in the rotary drive reduces the forces which have to be taken up by the outrigger and the main frame of the swathe, which thus can be made lighter as well. Moreover, a lighter rotor can follow the ground contour better.

1.2.5 Wearing materials

KRONE hay and forage machines are subjected to wear primarily at points which get into intensive contact to the crop, which includes all types of blade, but also sheet metal channels through which the crop is past at high speed. This chapter will render some examples from the forage harvester Big X.

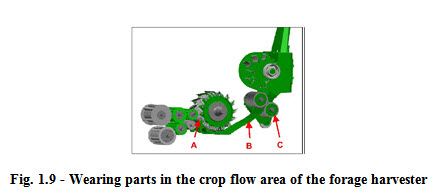

In the forage harvester, the maize is cut between the moving blades of the cutting drum and the stationary counter blade (A in Fig.1.9). On account of the high throughput capacities of these machines, wear occurs after a relatively short period of time. In order to optimize this unit, the blades and counter blades are coated with hard metal in parts.

In a special process, hard particles made of tungsten carbide bedded in a matrix are applied to the surface and primarily to the side edges of the counter blade. These particles have a hardness of up to 2000 VH.

The forage passes through a feed channel chamber (B in Fig.1.9) behind the cutting drum, which is made of Hardox on the lower side to ensure protection against wear. Hardox is sheet-metal material hardened and optimized especially for wear resistance produced by a Swedish manufacturer. By being hardened up to 500 HB and with a tensile strength of up to 1500 N/mm², Hardox ensures a multiple service life compared to normal types of steel in these conditions of use.

There are especially hard conditions for forage harvesters, in which a lot of sand and/or dust is taken in along with the maize. Here the service life of Hardox sheet metals is not enough either. In these cases sheet metals are used which have been armour-plated with a high carbide contents by weld cladding.

Further downstream, the maize then passes the so-called corn cracker, which consists of two fast rotating toothed rollers, which are located at a very close distance to each other. When passing through this gas, the maize corns are squeezed for better digestibility. These rollers are also subjected to a high degree of wear. They are manufactured from a pipe made of material Cf 45N, which is provided with a hardness of about 60 HRC.

1.2.6 Synthetic materials

In modern agricultural machinery, synthetic materials are employed in versatile forms. The most obvious use, however, is certainly the field of machine design.

Today, aesthetically shaped paneling dominates the market. In the automotive industry this target was achieved by deep drawing sheet metal.

At the relatively low unit numbers in agricultural engineering compared to the motor-vehicle industry this cannot be carried out economically. For this reason, paneling made of synthetic material is used.

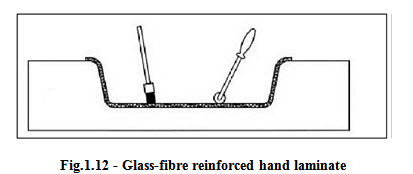

KRONE produces modern machine paneling made of glass-fiber reinforced plastic. In this process, glass fiber is placed in a mould, saturated with polyester resin and hardening agent.

In the so-called hand laminate process, glass fibre mats are coated by brush. In the more automated fibre spraying process, a special spray gun is used to spray resin, hardening agent and fibre into the mould. On the outside, the parts have a smooth surface ensured by the mould, which can also be dyed in multiple colours.

The inside is rough and can be linked up to laminated steel parts of the machine. This process is suitable for small to medium numbers, and stands out for its high mechanical stability at relatively low investment costs.

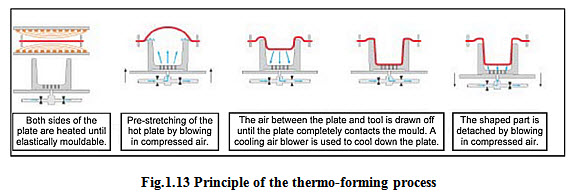

A plate or a film made of thermo-plastic material is clamped in a stenter frame, and then a suitable heat source is used to heat both The heated plate is pre-stretched by compressed air, and the moulding tool moves into moulding position by lifting the machine table. The air located between model and plate is drawn off. The atmospheric outside pressure presses the soft plate against the mould walls in such a manner that the contours are precisely copied. Subsequently the moulded material is cooled down by cooling air blower, and compressed air is used for demoulding.

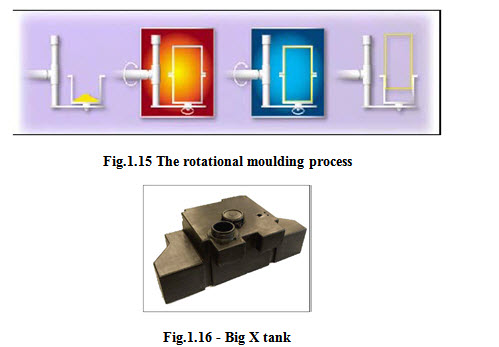

The last process to be presented here shall be the rotational moulding or rotational sintering process for the production of hollow bodies. In this process, a certain amount of fine polyethylene granulate is filled into a mould. The closed mould is then heated permanently rotating around two axes. The synthetic sides until fictile. When the fictile range has been made, the heat sources are removed. Material melts and settles on the inside of the mould at a uniform thickness. Subsequently the rotating mould is cooled down, opened, and the component is demoulded. The diesel tank of Big X, for example, is produced in this way.

On account of the low density of the polyethylene of only 0.93 g/cm³, this 960-litre tank has an empty mass of 60 kg, which is about 140 kg lighter than a comparable steel tank. The rotational moulding process can also be used to manufacture single-shell shapes, such as inside panelling of the cab. They are manufactured in pairs in one mould and are subsequently separated.

1.3. Abstract and outlook

The progress described in the materials of agricultural machinery took place in different periods ranging from some decades to a few years only. The optimization of various materials will certainly continue in the future. A strong development has to be expected, for example, in the metal matrix composite materials described for wear-resistant components. By combining metallic and ceramic materials to a composite, the typical advantages of both material classes can be used, whereby the property profile of the metal matrix / ceramic composite can be set precisely by varying the shape, size and volume percentage of the composite partner. The structure of the ceramic component also determines significantly the properties of the composite.

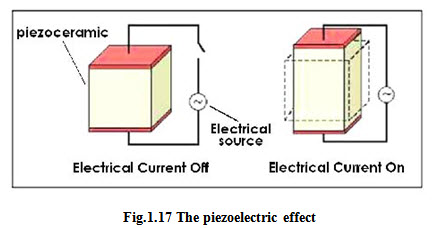

Moreover, it may also be possible that entirely new materials, so-called smart materials, which are being used in other branches already, may be introduced to agricultural engineering: piezoelectric materials, for example, are suitable for the production of components which can be shaped by applying electrical current.

Piezoelectric materials have two unique properties which are interrelated. When a piezoelectric material is deformed, it gives off a small but measurable electrical charge. Alternately, when an electrical current is passed through a piezoelectric material it experiences a significant increase in size (up to a 4 % change in volume).

Today already, this material is being used in the motor-vehicle industry, for example, as sensors for air bags or as actuators in the injection system. In agricultural engineering, it is theoretically conceivable, for example, to adapt the shape of a deep-digger body to various soil conditions or working speeds by electrical current.

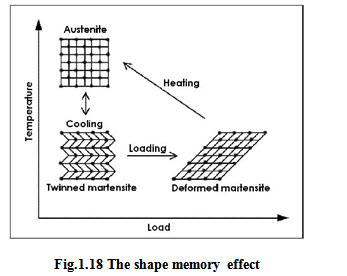

The so-called shape memory alloys also belong to the smart materials. Shape memory alloys (SMA's) are metals, which exhibit two very unique properties, pseudo-elasticity, and the shape memory effect. The most effective and widely used alloys include NiTi (Nickel - Titanium), CuZnAl, and CuAlNi.

The special feature in this alloy is that a phase twinned martensite is used, in which by heat the alloy is converted into another phase austenite without the component changing its size or shape. If a component made of twinned martensite is deformed by excessively high loads, it can be returned to its original shape by heating.

The special feature in this alloy is that a phase twinned martensite is used, in which by heat the alloy is converted into another phase austenite without the component changing its size or shape. If a component made of twinned martensite is deformed by excessively high loads, it can be returned to its original shape by heating.

Even if this technology certainly is relatively far away from use in everyday agricultural practice, deformed components which after an excessively load can be returned to their original shape by simple heating, would indeed by another distinct progress in typical materials for agricultural machinery

Reference: http://www.clubofbologna.org/ew/documents/Martensen-paper.pdf