Site pages

Current course

Participants

General

MODULE 1. Introduction to production of agricultur...

MODULE 2. Advance in material for tractor and agri...

MODULE 3. Advanced manufacturing techniques

MODULE 4. Heat treatment of steel

MODULE 5. Industrial lay out planning and quality ...

MODULE 6. Economics of process

MODULE 7. Techno economic feasibility of project r...

MODULE 8. Servo motors, drives and controllers

MODULE 9. CNC controllers for machine tools

MODULE 10. CNC programming

MODULE 11. Assembly and plant automation storage a...

LESSON 3. CUTTING TOOLS

3.1 Introduction

The cutting tool materials must possess a number of important properties to avoid excessive wear, fracture failure and high temperatures in cutting. The following characteristics are essential for cutting materials to withstand the heavy conditions of the cutting process and to produce high quality and economical parts:

3.1.1 Hardness

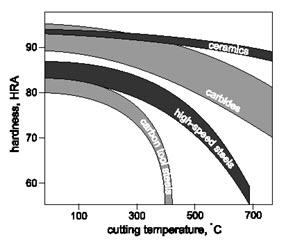

At elevated temperatures (so-called hot hardness) so that hardness and strength of the tool edge are maintained in high cutting temperatures. From Fig.3.1 shows hot hardness for different tool materials.

Fig.3.1 Hot hardness for different tool materials (Ref. Book by A.Bhattacharya)

3.1.2 Toughness

Ability of the material to absorb energy without failing. Cutting if often accompanied by impact forces especially if cutting is interrupted, and cutting tool may fail very soon if it is not strong enough.

3.1.3 Wear resistance

Although there is a strong correlation between hot hardness and wear resistance, later depends on more than just hot hardness. Other important characteristics include surface finish on the tool, chemical inertness of the tool material with respect to the work material, and thermal conductivity of the tool material, which affects the maximum value of the cutting temperature at tool-chip interface.

3.2 Needs and chronological development of cutting tool materials

With the progress of the industrial world it has been needed to continuously develop and improve the cutting tool materials and geometry;

to meet the growing demands for high productivity, quality and economy of machining

to enable effective and efficient machining of the exotic materials that are coming up with the rapid and vast progress of science and technology

for precision and ultra-precision machining

for micro and even nano machining demanded by the day and future.

It is already stated that the capability and overall performance of the cutting tools depend upon,

the cutting tool materials

the cutting tool geometry

proper selection and use of those tools

the machining conditions and the environments

Out of which the tool material plays the most vital role.

The relative contribution of the cutting tool materials on productivity, for instance, can be roughly assessed from Fig. 3.2

Fig. 3.2 Productivity raised by cutting tool materials.

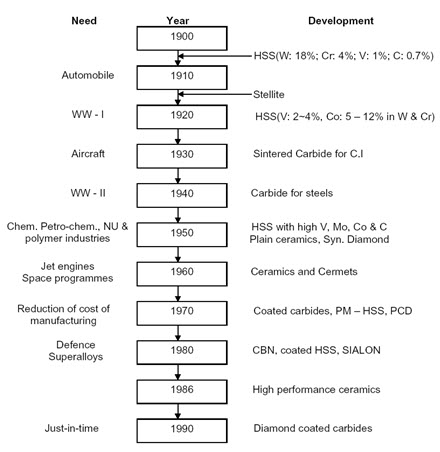

The chronological development of cutting tool materials is briefly indicated in Fig. 3.3

Fig. 3.3 Chronological development of cutting tool materials

3.3 Characteristics and applications of the primary cutting tool materials

(a) High Speed Steel (HSS)

Advent of HSS in around 1905 made a break through at that time in the history of cutting tool materials though got later superseded by many other novel tool materials like cemented carbides and ceramics which could machine much faster than the HSS tools.

The basic composition of HSS is 18% W, 4% Cr, 1% V, 0.7% C and rest Fe. Such HSS tool could machine (turn) mild steel jobs at speed only upto 20 ~ 30 m/min (which was quite substantial those days) However, HSS is still used as cutting tool material where;

the tool geometry and mechanics of chip formation are complex, such as helical twist drills, reamers, gear shaping cutters, hobs, form tools, broaches etc.

brittle tools like carbides, ceramics etc. are not suitable under shock loading

the small scale industries cannot afford costlier tools

the old or low powered small machine tools cannot accept high speed and feed.

The tool is to be used number of times by resharpening.

With time the effectiveness and efficiency of HSS (tools) and their application range were gradually enhanced by improving its properties and surface condition through -

Refinement of microstructure

Addition of large amount of cobalt and Vanadium to increase hot

hardness and wear resistance respectively

Manufacture by powder metallurgical process

Surface coating with heat and wear resistive materials like TiC, TiN, etc by Chemical Vapour Deposition (CVD) or Physical Vapour Deposition (PVD)

The commonly used grades of HSS are given in Table 3.1.

Table 3.1 Compositions and types of popular high speed steels

|

Type |

C |

W |

Mo |

Cr |

V |

Co |

Rc |

|

T-1 |

0.70 |

18 |

|

4 |

1 |

|

|

|

T-4 |

0.75 |

18 |

|

4 |

1 |

5 |

|

|

T-6 |

0.80 |

20 |

|

4 |

2 |

12 |

|

|

M-2 |

0.80 |

6 |

5 |

4 |

2 |

|

64.7 |

|

M-4 |

1.30 |

6 |

5 |

4 |

4 |

|

|

|

M-15 |

1.55 |

6 |

3 |

5 |

5 |

5 |

|

|

M-42 |

1.08 |

1.5 |

9.5 |

4 |

1.1 |

8 |

62.4 |

Addition of large amount of Co and V, refinement of microstructure and coating increased strength and wear resistance and thus enhanced productivity and life of the HSS tools remarkably.

(b) Stellite

This is a cast alloy of Co (40 to 50%), Cr (27 to 32%), W (14 to 19%) and C (2%). Stellite is quite tough and more heat and wear resistive than the basic HSS (18 – 4 – 1) But such stellite as cutting tool material became obsolete for its poor grindability and specially after the arrival of cemented carbides.

(c) Sintered Tungsten carbides

The advent of sintered carbides made another breakthrough in the history of cutting tool materials.

• Straight or single carbide

First the straight or single carbide tools or inserts were powder metallurgically produced by mixing, compacting and sintering 90 to 95% WC powder with cobalt. The hot, hard and wear resistant WC grains are held by the binder Co which provides the necessary strength and toughness. Such tools are suitable for machining grey cast iron, brass, bronze etc. which produce short discontinuous chips and at cutting velocities two to three times of that possible for HSS tools.

• Composite carbides

The single carbide is not suitable for machining steels because of rapid growth of wear, particularly crater wear, by diffusion of Co and carbon from the tool to the chip under the high stress and temperature bulk (plastic) contact between the continuous chip and the tool surfaces. For machining steels successfully, another type called composite carbide have been developed by adding (8 to 20%) a gamma phase to WC and Co mix. The gamma phase is a mix of TiC, TiN, TaC, NiC etc. which are more diffusion resistant than WC due to their more stability and less wettability by steel.

• Mixed carbides

Titanium carbide (TiC) is not only more stable but also much harder than WC. So for machining ferritic steels causing intensive diffusion and adhesion wear a large quantity (5 to 25%) of TiC is added with WC and Co to produce another grade called Mixed carbide. But increase in TiC content reduces the toughness of the tools. Therefore, for finishing with light cut but high speed, the harder grades containing upto 25% TiC are used and for heavy roughing work at lower speeds lesser amount (5 to 10%) of TiC is suitable.

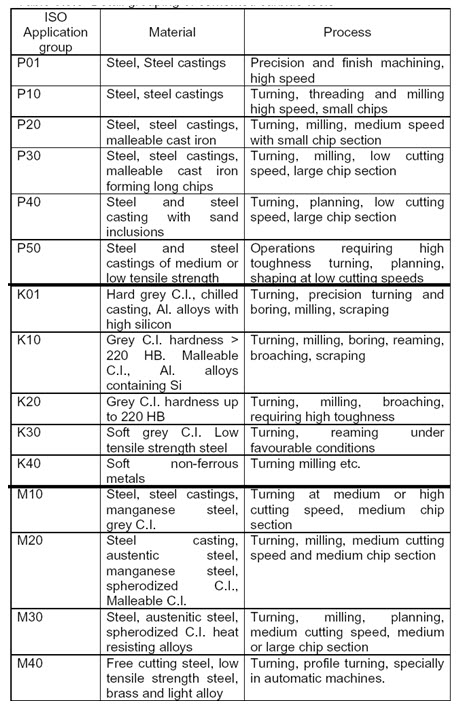

• Gradation of cemented carbides and their applications

The standards developed by ISO for grouping of carbide tools and their application ranges are given in Table 3.2.

Table 3.2 Broad classification of carbide tools.

ISO code |

Colour Code |

Application |

|

P |

For machining long chip forming common material like plain carbon and low alloy steels |

|

|

M |

For machining long or short chip forming ferrous material like stainless steel |

|

|

K |

For machining short chipping ferrous and non ferrous material like cast iron, brass etc. |

K-group is suitable for machining short chip producing ferrous and nonferrous metals and also some non metals.

P-group is suitably used for machining long chipping ferrous metals i.e. plain carbon and low alloy steels.

M-group is generally recommended for machining more difficult-tomachine materials like strain hardening austenitic steel and manganese steel etc.

Each group again is divided into some subgroups like P10, P20 etc., as shown in Table 3.3 depending upon their properties and applications.

Table 3.3 Detail grouping of cemented carbide tools

The smaller number refers to the operations which need more wear resistance and the larger numbers to those requiring higher toughness for the tool.

(d) Plain ceramics

Inherently high compressive strength, chemical stability and hot hardness of the ceramics led to powder metallurgical production of indexable ceramic tool inserts since 1950. Table 3.4 shows the advantages and limitations of alumina ceramics in contrast to sintered carbide. Alumina (Al2O3) is preferred to silicon nitride (Si3N4) for higher hardness and chemical stability. Si3N4 is tougher but again more difficult to process. The plain ceramic tools are brittle in nature and hence had limited applications.

Table 3.4 Cutting tool properties of alumina ceramics

|

Advantages |

shortcoming |

|

Very high hardness |

Poor toughless |

|

Very high hot hardness |

Poor tensile strength |

|

Chemical stability |

Poor TRS |

|

Antiwelding |

Low thermal conductivity |

|

Less diffusivity |

Less density |

|

High abrasion resistance |

|

|

High melting point |

|

|

Very low thermal conductivity* |

|

|

Very low thermal expansion coefficient |

|

* Cutting tool should resist penetration of heat but should disperse the heat throughout the core.

Basically three types of ceramic tool bits are available in the market;

Plain alumina with traces of additives – these white or pink sintered inserts are cold pressed and are used mainly for machining cast iron and similar materials at speeds 200 to 250 m/min

Alumina; with or without additives – hot pressed, black colour, hard and strong – used for machining steels and cast iron at VC = 150 to250 m/min

Carbide ceramic (Al2O3 + 30% TiC) cold or hot pressed, black colour, quite strong and enough tough – used for machining hard cast irons and plain and alloy steels at 150 to 200 m/min.

The plain ceramic outperformed the then existing tool materials in some application areas like high speed machining of softer steels mainly for higher hot hardness as indicated in Fig. 3.1

However, the use of those brittle plain ceramic tools, until their strength and toughness could be substantially improved since 1970, gradually decreased for being restricted to

uninterrupted machining of soft cast irons and steels only

relatively high cutting velocity but only in a narrow range (200 ~ 300 m/min)

requiring very rigid machine tools

Advent of coated carbide capable of machining cast iron and steels at high velocity made the then ceramics almost obsolete.

References:

http://me.emu.edu.tr/me364/ME364_cutting_materials.pdf

http://nptel.iitm.ac.in/courses/Webcourse-contents/IIT%20Kharagpur/Manuf%20Proc%20II/pdf/LM-15.pdf