Site pages

Current course

Participants

General

MODULE 1. Introduction to production of agricultur...

MODULE 2. Advance in material for tractor and agri...

MODULE 3. Advanced manufacturing techniques

MODULE 4. Heat treatment of steel

MODULE 5. Industrial lay out planning and quality ...

MODULE 6. Economics of process

MODULE 7. Techno economic feasibility of project r...

MODULE 8. Servo motors, drives and controllers

MODULE 9. CNC controllers for machine tools

MODULE 10. CNC programming

MODULE 11. Assembly and plant automation storage a...

LESSON 5. CUTTING TOOLS FOR FINISHING OPERATIONS

5.1 Introduction

As the name of this group of abrasive operations suggests, their objective is to achieve superior surface finish up to mirror-like finishing and very close dimensional precision. The finishing operations are assigned as the last operations in the single part production cycle usually after the conventional or abrasive machining operations, but also after net shape processes such as powder metallurgy, cold flashless forging, etc.

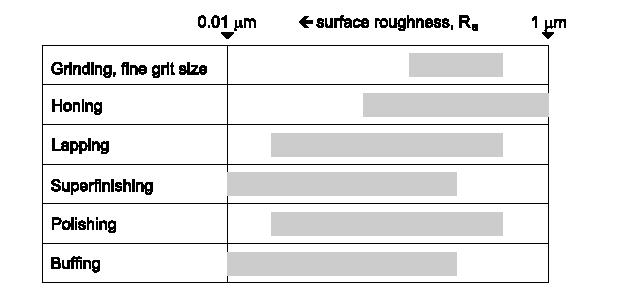

The finishing processes discussed in this section include honing, lapping, superfinishing, polishing, and buffing. The typical surface finishes for these operations are presented in the fig.1. Also presented for comparison are surface roughness values for fine grit size grinding.

Fig. 5.1 Typical surface finishing operations

5.2 Honing

Honing is a finishing process performed by a honing tool, which contains a set of three to a dozen and more bonded abrasive sticks. The sticks are equally spaced about the periphery of the honing tool. They are held against the work surface with controlled light pressure, usually exercised by small springs. The honing tool is given a complex rotational and oscillatory axial motion, which combine to produce a crosshatched lay pattern of very low surface roughness:

Fig. 5.2 Schematics of honing process showing the honing tool

In addition to the surface finish of about 0.1 µm, honing produces a characteristic crosshatched surface that tends to retain lubrication during operation of the component, thus contributing to its function and service life. A cutting fluid must be used in honing to cool and lubricate the tool and to help remove the chips.

A common application of honing is to finish the holes. Typical examples include bores of internal combustion engines, bearings, hydraulic cylinders, and gun barrels.

5.3 Lapping

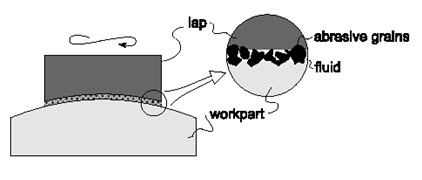

In lapping, instead of a bonded abrasive tool, oil-based fluid suspension of very small free abrasive grains (aluminum oxide and silicon carbide, with typical grit sizes between 300 and 600) called a lapping compound is applied between the workpiece and the lapping tool.

The lapping tool is called a lap, which is made of soft materials like copper, lead or wood. The lap has the reverse of the desired shape of the workpart. To accomplish the process, the lap is pressed against the work and moved back and forth over the surface in a figure-eight or other motion pattern, subjecting all portions of the surface to the same action. Lapping is sometimes performed by hand, but lapping machines accomplish the process with greater consistency and efficiency.

Fig. 5.3 Schematics of lapping process

The cutting mechanism in lapping is that the abrasives become embedded in the lap surface, and the cutting action is very similar to grinding, but a concurrent cutting action of the free abrasive particles in the fluid cannot be excluded.

Lapping is used to produce optical lenses, metallic bearing surfaces, gages, and other parts requiring very good finishes and extreme accuracy.

5.4 Superfinishing

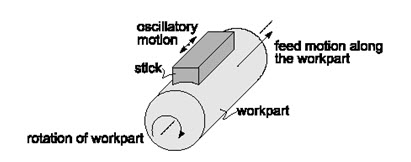

Superfinishing is a finishing operation similar to honing, but it involves the use of a single abrasive stick. The reciprocating motion of the stick is performed at higher frequency and smaller amplitudes. Also, the grit size and pressures applied on the abrasive stick are smaller. A cutting fluid is used to cool the work surface and wash away chips.

Fig. 5.4 Schematics of the superfinishig process

In superfinishing, the cutting action terminates by itself when a lubricant film is built up between the tool and work surface. Thus, superfinishing is capable only of improving the surface finish but not dimensional accuracy. The result of these operating conditions is mirror like finishes with surface roughness values around 0.01 µm. Superfinishing can be used to finish flat and external cylindrical surfaces.

5.5 Polishing and buffing

Polishing is a finishing operation to improve the surface finish by means of a polishing wheel made of fabrics or leather and rotating at high speed. The abrasive grains are glued to the outside periphery of the polishing wheel. Polishing operations are often accomplished manually.

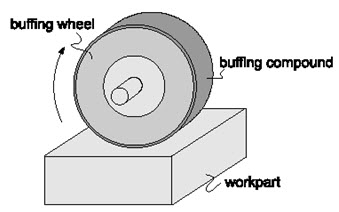

Buffing is a finishing operation similar to polishing, in which abrasive grains are not glued to the wheel but are contained in a buffing compound that is pressed into the outside surface of the buffing wheel while it rotates. As in polishing, the abrasive particles must be periodically replenished. As in polishing, buffing is usually done manually, although machines have been designed to perform the process automatically.

Fig. 5.5 Schematics of the buffing operation.

Polishing is used to remove scratches and burrs and to smooth rough surfaces while buffing is used to provide attractive surfaces with high luster.

Reference: http://me.emu.edu.tr.