Site pages

Current course

Participants

General

Module- 1 Scope and importance of food processing....

Module- 2 Processing of farm crops; cereals, pulse...

Module- 3 Processing of animal products

Module- 4 Principal of size reduction, grain shape...

Module- 5 Theory of mixing, types of mixtures for ...

Module- 6 Theory of separation, size and un sized ...

Module- 7 Theory of filtration, study of different...

Module- 8 Scope & importance of material handl...

Lesson. 21 Type of Separators

In food industries, the operations of separating raw products including cleaning and grading are performed by the different engineering properties. Various types of separation equipments have been designed and developed on the basis of properties of the products.

The separation equipment can be classified depending upon the following characteristics of the raw materials;

-size, shape, specific gravity and surface roughness

-magnetic properties, aerodynamic properties, colour, electrical properties

-dielectric properties, rheological properties

A classification of separation techniques according to phases (type of mixture) involved are given as;

|

Type of mixture |

Techniques |

|

Liquid-liquid |

Distillation Extraction Decantation Dialysis and electro-dialysis Parametric pumping |

|

Solid-solid |

Screening Leaching Floatation Air classification |

|

Solid-gas |

Cyclonic Air filtration Scrubbing Electrostatic precipitation |

|

Solid-liquid |

Sedimentation Centrifugation Filtration Membrane separation |

Screening fundamentals

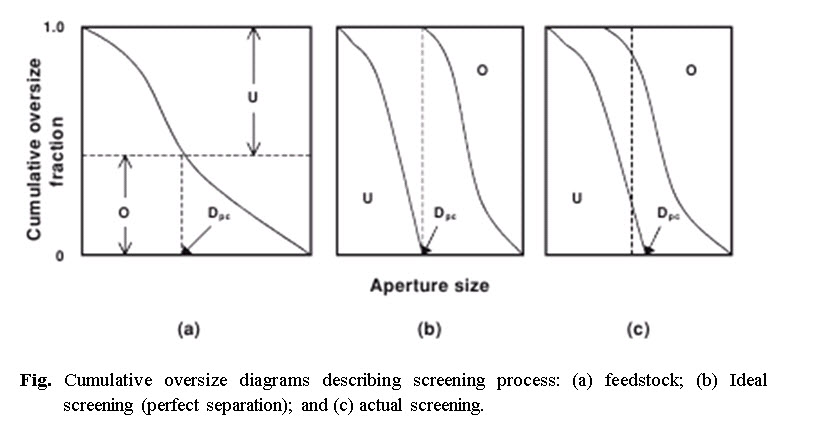

The objective of a screening operation is to separate a feed stream into two fractions, an underflow that is passed through the screen and an overflow that is rejected by the screen. An ideal screen sharply separates the feed in such a way that the smallest particle in the overflow is just larger than the largest particle in the underflow. Such an ideal separation would define a cut diameter, Dpc, representing the point of separation between the fractions. For an ideal operation, a plot of screen opening against cumulative fraction retained would have the shape shown in Fig.b.

As can be seen, the largest particle of the underflow (U) has the same size as the smallest particle of the overflow (O). In practice, however, the plot would have the shape illustrated in Fig. 3.1c, in which there is an overlap; the underflow has an appreciable amount of particles larger than the desired cut diameter, while the overflow has particles smaller than such desired cut diameter. That is the actual screens don’t yield a sharp separation. It has been observed that with standard testing screen, the overlap is smaller when particles are spherical (or close to a spherical shape) and is larger when particles are needle-like, fibrous or tend to agglomerate. The main problems encountered in screening result from sample stickiness, sieve blockage, and agglomeration. Commercial screens usually give poorer performance than testing screens of the same mesh handling the same feed mixture. All these problems increase exponentially as the screen aperture decreases.

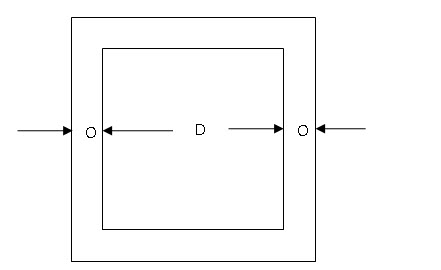

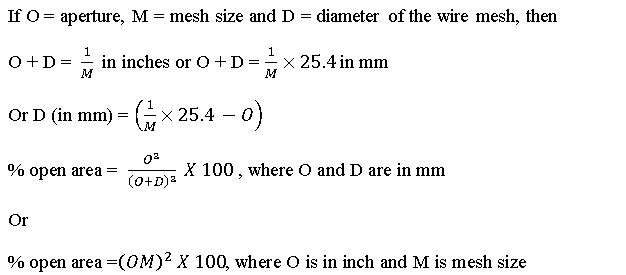

Percentage open area of a mesh

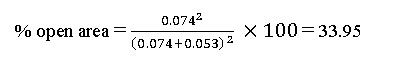

Example 3.1 Calculate the opening size (Aperture) in mm of a 200-mesh screen of Tyler standard screen series with a wire of 0.053 mm diameter. Determine the percentage open area for this mesh size.

Solution:

O = (1/200 x 25.4 – 0.053) = 0.074 mm

Generally, in food industries, screens are constructed by perforated sheet metal or woven wire mesh. The opening in perforated metal sheets may be round, oblong or triangular. The opening in wire mesh is square or rectangle.