Site pages

Current course

Participants

General

Module- 1 Scope and importance of food processing....

Module- 2 Processing of farm crops; cereals, pulse...

Module- 3 Processing of animal products

Module- 4 Principal of size reduction, grain shape...

Module- 5 Theory of mixing, types of mixtures for ...

Module- 6 Theory of separation, size and un sized ...

Module- 7 Theory of filtration, study of different...

Module- 8 Scope & importance of material handl...

Lesson 24 Pneumatic separation

24.1 Introduction

Pneumatic separation is the process of using air to lift light, chaffy and dusty materials out of the grain while heavier materials move downward. Aerodynamic characteristic of particle mixtures are important for cleaning.

The pneumatic separation is based on the difference in aerodynamic properties of various constituents of the mixture. The aerodynamic property of a particle depends upon its shape, size, surface and orientation with respect to air current. Aspirator and pneumatic separator both use terminal velocity of the grain to separate different fractions. The velocity of air required to suspend particles in a rising air current.

In this separator, the fan is placed at the intake end of the machine which creates higher pressure than atmospheric pressure. The high pressure air blast separates the materials. The mixer of products is introduced in to a confined rising air stream, the particles with low terminal velocities are lifted by the current where as the particles with higher terminal velocities than air velocity fall down. The air velocity can be adjusted by altering the speed of fan or by changing the opening of air inlet.

The aspirator has a fan at the air discharge point which creates a vacuum or negative pressure within the machine. The scalping separator is a type of aspirator separator in which rough separation is performed. The mixture of the grain is dropped in to a rising air column which has a velocity slightly lower than the terminal velocity of the heavy grains. The leaves, trash and lighter particles rise with the air and are deposited in an enlarged settling chamber. The denser grains fall through the incoming air in to a container.

The fractionating aspirator is another type of separator. The mixer of grain is fed in to the lower end of the expanding air column, the heavy grain fall against the air flow while the lighter particles are lifted. The grains with high terminal velocity are dropped in the expanding column. The lighter fractions of the grains are discharged as per the relative through different outlets positioned in the column. Thus the mixture is separated in to various fractions.

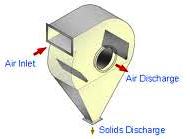

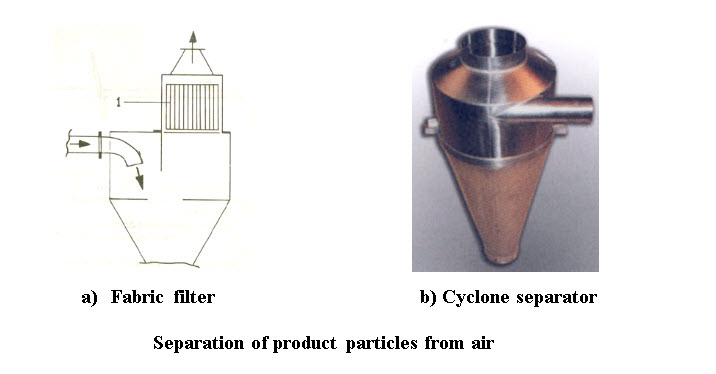

For separation of product particles from air, air-product separators are used. Cyclones are mostly used to collect the particles. Cyclone is a device which removes the bulk of the product particle from the conveying air stream by centrifugal force. In some cyclone, a fabric filter is attached to remove residual dust and fine product particles from the air stream.

The volumetric flow rate of air depends on the necessary air velocity and pipe or duct size used in the system. In this systems, fans and blowers with high voulmetric flow rates and lower pressures to positive displacement compressors producing high pressures are used.