Site pages

Current course

Participants

General

Module 1. Moisture content and its determination.

Module 2. EMC

Module 3. Drying Theory and Mechanism of drying

Module 4. Air pressure within the grain bed, Shred...

Module 6. Study of different types of dryers- perf...

Module 5. Different methods of drying including pu...

Module 7. Study of drying and dehydration of agric...

Module 8. Types and causes of spoilage in storage.

Module 9. Storage of perishable products, function...

Module 10. Calculation of refrigeration load.

Module 11. Conditions for modified atmospheric sto...

Module 12. Storage of grains: destructive agents, ...

Module 13. Storage of cereal grains and their prod...

Module 14. Storage condition for various fruits an...

Module 15. Economics aspect of storage

Lession–38 Design of Silos

The agricultural granular product like cereals which are mostly stored in silo, For the design of silos the knowledge of characteristics of grain like bulk density, internal angle of friction, coefficient of friction on the walls is needed. The walls of the silos have to design by considering self weight and loads of the grain during construction. The silos walls are subjected to two main forces or thursts, (1) the horizontal thurst due to loading of material which tries to open up the silo and (2) the vertical pressure which is generated due to loading of material on the walls. The speed of filling of granular material affects the stress development on silo. When the material is filled very rapidly without any compaction other than the compaction produced in the operation, the greatest forces are obtained for the lateral thurst while the apparent density and the angle of internal friction of the material are at minimum values. On the contrary, when the grain is filled at such a slow rate which provides every possibility of compaction, the greatest forces are obtained for the vertical pressure. In this case the bulk density and the angle of internal friction of material are at maximum values.

The following terminology is useful for design of storage structures

- Bulk density

The bulk density of a granular product is the density measured without the influence of any compression on the product. The bulk density depends on particle density, its shape and the manner in which the constituent particles are packed or positioned with respect to each other. Bulk density is also defined as weight of grains per unit bulk volume (including porosity / voids).

Bulk Density, ![]()

Where, W = weight of grains, Vv = void volume and Vg = grain volume

- True density

The true density represents the actual density of particle. It is determined by, liquid displacement method. The liquid generally used is toluene. Toluene is filled in, a measuring cylinder and the volume is recorded. Then, 100 g grain is put in cylinder. The rise in volume of toluene in cylinder is noted. True density is the ratio of weight of grain and the difference in volume of toluene. True density is weight of kernel per unit true volume (excluding porosity/voids).

True Density,![]()

Where, W = weight of grains, and Vg = grain volume

- Apparent density

For grains, the bulk density is increased when the grains are compressed. "During this process reorientation and settling of particles take place. As a result air percolates out of the bulk mass and the volume decreases. This increases the bulk density. The density of compressed mass or bulk is called the 'apparent density'. The value of apparent density is higher by 20% than the normal bulk density. In design of a silo, the apparent density of grain is taken into account, because of compaction, the bottom layer or base layer of silo has maximum density whereas the top layer has minimum density.

- External friction

External friction is friction between grain mass of kernels and the wall of bin or a surface.

- Internal friction

Friction of the kernels or grains against each other is known as internal friction.

- Angle of internal friction

The sliding stress between the grain to grain gives the frictional resistance per unit of surface area of the grain against the grain. This is called the angle of internal friction. Coefficient of friction μ between granular materials is equal to tangent of the 'angle of internal friction' for that material. Higher values of angle of internal friction indicate that the material is cohesive. The lower values of angle of internal friction are indicative of easy flowing products.

- Coefficient of friction

If 'F' is the horizontal force or pull and N is the vertical force caused by the total weight of grain, the coefficient of friction μ can be given by ![]()

The characteristics values of the granular material which cause greatest stresses should be taken into account while determining the lateral.and vertical pressures of storage silo. These values are function of the silo wall nature. For smooth walled silo the greatest vertical and lateral pressure be estimated with maximum values of bulk density and. angle of internal friction while the minimum value of angle of friction of grains on the walls be taken. Whereas for silos with rough walls, the lateral pressure should be calculated with values of minimum bulk density, minimum angle of internal friction and the minimum angle of friction of the grains on the walls. The greatest vertical pressure should be estimated with maximum bulk density, maximum angle of internal friction, and the minimum angle of friction of the grains on the walls.

38.1 Grain Pressure Theories

The grain pressure in bins were first calculated as being a semi liquid of same density as the grains. The lateral pressure was first calculated using the hydrostatic formula.

Where,

Pl = wh ………………………………………………………(1)

Pl = lateral pressure exerted by the grain on the bin wall, kg/m2

w = density of grain, kg/m3

h = depth of grain from the top of the bin surface, m

This formula has serious deficiencies because many structures buckled under the vertical load arising from the friction of the grain on the walls. The formula (1) was modified to incorporate a factor 'K ' known as Rankine's earth pressure coefficient. The Rinkine's formula is based on the following principle, the resistance to displacement by sliding along a given plane in a loose granular mass is equal to the normal pressure exerted between the parts of the mass on either side of the plane, multiplied by the specific constant. The formula (1) when multiplied by the factor 'K ' is known as Rankine's earth pressure coefficient.

Pl = Kwh

Where,

K = Rankine's coefficient

![]()

Φ= angle of internal friction of the grain = natural angle of repose

Therefore,

![]() ....................................................... (2)

....................................................... (2)

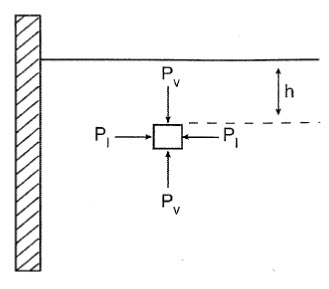

Fig.38.1 Pressures on an element of soil behind a vertical wall

The whole weight of the grain was assumed to be transferred to the bottom of the beam. The Rankine theory with horizontal soil surface behind a vertical wall is shown in Figure. Consider an element of soil at depth 'h'. The vertical pressure acting on this element Pv and the horizontal pressure Pl is active pressure at failure.

![]()

OR

Pl = K Pv …………………………………………..(3)

K = Rankine coefficient = Coefficient of earth pressure

![]()

The above Rankine formula (3) is used for determination of pressure induced by granular materials against retaining wall in shallow bins.

- The scientist Airy developed a theory for pressure induced by granular materials against retaining wall or in shallow bins. The lateral pressure exerted by grains in a shallow bin can be given by following Airy's equation

![]()

Where,

w = grain bulk density

h = depth of grain to point under consideration

μ = coefficient of friction of grain on grain

= tan Φ, Φ is angle of internal friction

μ' = tan Φ', Φ' is the angle of wall friction.

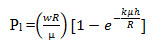

- The scientist Janssen took into account the friction between the grain and bin wall and, proposed the following formula for 'deep bins'.

Where,

Pl = lateral pressure

R = hydraulic radius

w = grain bulk density (unit weight of grain)

µ = coefficient of friction of the grain on the wall

= tan Φ

![]()

h = depth of grain

38.2 Problems of Silo Design

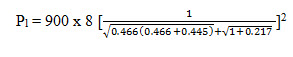

38.2.1 Wheat weighing 900 kg/m3 is loaded in a circular concrete silo of 3 m internal diameter and a clear height of 8 m. The angle of internal friction for wheat is 25° and that for wheat and concrete is 24°. Applying Airy theory, calculate the maximum lateral pressure at the bottom of bin section.

Solution

Lateral pressure against a shallow bin wall is

![]()

Where,

Pl = lateral pressure

w = bulk density of grain = 900 kg/m3

h = depth of bin (point) under consideration = 8 m

μ = coefficient of friction of grain to grain

= tan Φ, Φ is the angle of internal friction = 250

= tan 250 = 0.466

μ' = coefficient of friction of grain to wall

= tan Φ' , Φ' is the angle of external (wall) friction = 240

= tan 240 = 0.445

So,

![]()

Pl= 2338.5 kg/m2

38.2.2 A RC.C cylindrical grain storage bin has internal diameter of 5 m and is 20 m deep. It is completely filled with paddy weighing 600 kg/m3. The angle of internal friction for paddy can be taken as 350, while the angle of friction between paddy and bin wall is 30°. The ratio of horizontal and vertical pressure intensity k, is 0.4. Calculate the lateral pressure intensity at 4.0 m and 18 m depth using Janssen theory.

Solution

Lateral pressure against a deep bin wall as par Janssen theory is

Where,

Pl = lateral pressure

w = grain bulk density (unit weight of grain) = 600 kg/m3

R = hydraulic radius =D/4 = 5/4 =1.25 m

µ = coefficient of friction of the grain on the wall

= tan Φ= tan 300 = 0.577

K= Pl/PV = 0.4

h = depth of grain = 4.0 m and 18 m

Substituting the values of 4.0 m and 18.0 m depths in above equation, we get