Site pages

Current course

Participants

General

Module 1: Formation of Gully and Ravine

Module 2: Hydrological Parameters Related to Soil ...

Module 3: Soil Erosion Processes and Estimation

Module 4: Vegetative and Structural Measures for E...

Keywords

29 March - 4 April

5 April - 11 April

12 April - 18 April

19 April - 25 April

26 April - 2 May

Lesson 31 Permanent Structures - I

31.1 Concrete Dam

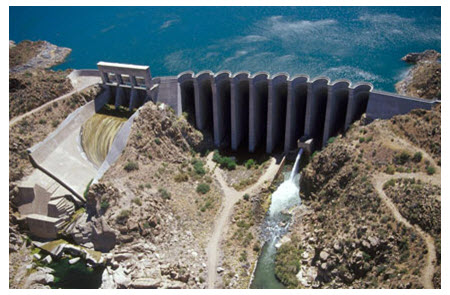

A concrete dam is a structure designed and built for the purpose of holding back water and is constructed across the path of a river or a stream. Dams are built for a variety of reasons, including flood control, power generation, drinking water supply, irrigation, etc. A concrete dam is the strongest type of dam built in modern times and may take several forms. Concrete itself is a building material made from water, cement, sand and gravel, or aggregate. Dams constructed using concrete have three basic designs. An arch dam is a curved, relatively thin curtain of concrete, with the concave side of the curve facing downstream. This type of dam is made of solid concrete that is reinforced with steel. It relies on the pressure of the water behind it to add strength as the components of the resulting force push the sides of the dam into the walls on either side. Arch dams are particularly well suited for areas where a river flows at the bottom of steep canyons or gorges with solid rock at the banks. Some of the important dams in India are Bhakra (Punjab), Idduki (Kerala), Sardar Sarovar (Gujarat), Almaty (Karnataka), etc.

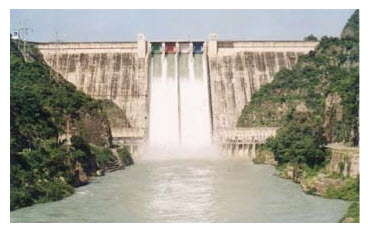

A gravity dam, as shown in fig. 31.1, is a type of dam that relies on its own mass to keep it stable and to hold back water. Gravity dams are often massive structures. The dam is made of concrete, but the main portion of its interior has core fill of rock rather than solid concrete. A gravity dam is usually not curved, and a cross section will resemble a right triangle, with the right angle at the bottom on the side facing the water and the side facing away from the water sloping downward so that the dam is thicker at the bottom. Gravity dams are better for areas where there is no firm bedrock or canyon walls for anchorage.

The third main type of concrete dam is the arch-gravity dam, which combines the features of both the arch dam and the gravity dam. Arch-gravity dams are curved dams that use the principle of the arch to bolster their strength but are much thicker than a typical arch dam and have a core of fill. They are designed so that their massive weight, combined with the increased strength of an arch over a straight line structure, will keep the dam in place and hold back the water.

Fig. 31.1. Bhakra Dam, a concrete dam in the India. (Source: http://www.realtyfact.com/bhakra-dam/)

31.2 Flood Dam

A flood dam, as shown in fig. 31.2, operates as part of a flood control system to protect communities from uncontrolled flood waters. Such dams do not create reservoirs to store water for use in the future, nor do they generate hydroelectric power. They can be installed by government agencies and communities, and are subjected to regulation for safety. A flood dam needs to meet building guidelines and regulators can inspect it periodically to confirm if it is in good working order. In heavy rains, or when runoff from upstream becomes heavier than usual, the flood dam action starts. It retains water and controls its release to slowly allow levels of lakes and rivers to stabilize. In addition to protecting communities from flood waters, this measure also limits topsoil loss and other environmental problems that can occur in severe flooding. When conditions return to normal, the flood control dams can go back into a dormant mode.

Construction of large dams requires certain favourable site characteristics, such as a solid (rock) subbase, strong and stable (rock) sides, narrow section of the river, relatively steeper river gradient, no dominant seismic hazard in the region (however, dams are designed and constructed even in high seismic regions by design modifications), etc. Everywhere such specific site characterics are not found. Hence, the sites for high dam construction are limited. High dams constructed in flatter terrain involve large area inundation that displaces people causing misery to them. Stopping of the natural flow of a river, rehabitation and resettlement issues for the displaced persons, loss of forest land, methane production from the vegetation submerged under the reservoir water, are some of the major environmental issues and concerns in India these days.

Fig. 31.2. Flood Dam (India’s hydroelectric projects, such as this dam on the River Teesta). (Source: http://www.nature.com/news/flood-of-protest-hits-indian-dams-1.11932)

31.3 Gabions

Gabion walls are flexible structures where the design is based on the mass of the gabions providing stability against the over turning forces due to the soil and surcharges, as shown in fig. 31.3.

Fig. 31.3. PVC coated Gabions. (Source: http://www.burdens.co.uk/sites/default/files/literature/ENVIROMESH_BROCHURE.pdf)

Types of Gabion Structures

(a) Box-Shaped Gabion

Gabion box-shaped structure is the most popular type of gabions of universal application. This means that if you wish, you can leave all attempts to optimize the design and just use the box-shaped gabions of most appropriate size. They have a classic structure - rectangular wire mesh filled with stones, and can be used for the construction of retaining walls, building mounds and banks, or for landscaping, Fig. 31.4 shows the box shaped gabion.

Fig. 31.4. Box-Shaped Gabion. (Source: http://www.burdens.co.uk/sites/default/files/literature/ENVIROMESH_BROCHURE.pdf)

Gabions box-Large (Jumbo Gabions)

When it comes to fast large-area coverage, we recommend the use of Jumbo - increased gabion structures, which can reach a length to 6 meters. This allows saving time for example, when installing a retaining wall or terrace, where the decisive importance is the length of the object. Such gabion structures could save you money, at least in the installation.

(b) Reno Mattresses

Reno Mattresses is another type of box gabion structures, which differs from other gabions in length and height. The principle of the device of this type of gabions is that it often has a height of only a few centimeters and is used when one wants to quickly cover a large area and do not lift it, but just strengthen it.

(c) Sack Gabions

Gabion structures in the form are recommended for the erection of towers. Of course, the usual box-shaped gabions are also suitable for this, but you can not lose sight of the design idea for your project: perhaps it is based on rounded objects and the absence of any kind whatsoever angles.

Application

Roadway Protection, Retaining Walls, Rock fall Protection, Bridges and Culverts Protection, Coastline Structure and Protection, Channel Lining. Roadway Protection: The protection of highways and roads from environmental disasters are facilitated with the use of R gabions that stabilize the slopes protecting the shoulders.

Retaining Walls

Gabions used as retaining walls are functional, economical solution and a good alternative to other types of retaining structures due to their flexibility and permeability, as sown in fig. 31.5.

Fig. 31.5. PVC coated woven wire gabions being used as a high retaining wall. (Source: http://www.burdens.co.uk/sites/default/files/literature/ENVIROMESH_BROCHURE.pdf)

Rock Fall Protection

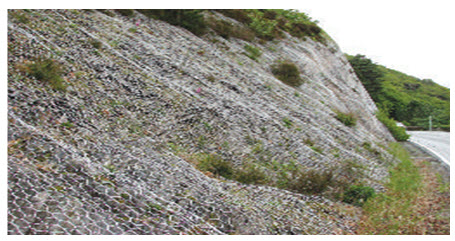

Rolls of fabric with lacing, done by joining together, are provided as a blanket to cover the surface of the slopes to protect any infrastructure built on the foot of the slopes against rock fall. Gabion constructed as retaining wall is an alternative, as illustrated in fig. 31.6.

Fig. 31.6. Rock fall protection netting. (Source: http://www.burdens.co.uk/sites/default/files/literature/ENVIROMESH_BROCHURE.pdf)

Bridges and Culverts Protection

Bridge abutments and culverts are potentially at risk of scouring during heavy rains and strong flow of water. Gabion boxes and mattresses can be used as abutments and protective structure that aid the flow of water avoiding the danger of erosion due to their good permeability characteristics.

Coastline Structure and Protection

Gabions and mattresses are highly resistant to corrosion and other environmental effects which are suitable for marine works such as: retaining walls, ramps, beach protection, small jetties, groins, and piers built at great speed and minimum cost. The use of gabions and mattresses dissipate wave energy conserving beaches from being eroded.

Channel Lining

Channels are protected using gabion and mattress structures against erosion which control and guide the movement of water naturally.

Boundary or Security Fences

Units can be used as fences which are cost effective as compared to concrete fences.

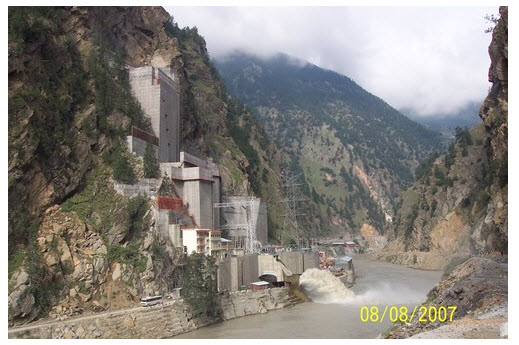

31.4 Coffer Dam

It is an enclosure constructed around the construction site to exclude water so that the construction can be done in dry. A coffer dam is thus a temporary dam constructed for facilitating construction. These structures are usually constructed on the upstream of the main dam to divert water into a diversion tunnel (or channel) during the construction of the dam. When the flow in the river during construction of hydraulic structures is not much, the site is usually enclosed by the coffer dam and pumped dry. Sometimes a coffer dam on the downstream of the dam is also required. Fig. 31.7 shows a coffer dam.

Fig. 31.7. Coffer dam at Karcham, Himanchal Pradesh, India. (Source: http://www.alltravels.com/india/himachal-pradesh/morang/photos/current-photo-80811149)

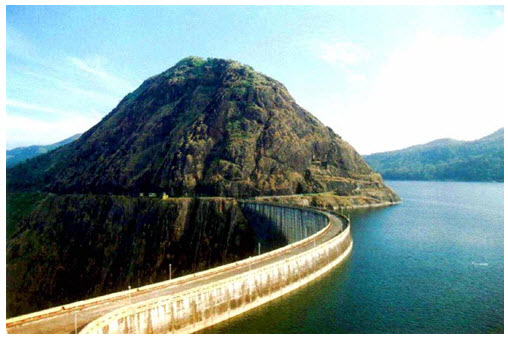

31.5 Concrete Arch Dam

Concrete arch dams are built in narrow, steep-walled canyons. The canyon walls take up the thrust exerted by the arch and the pressure of the water. Such dams can be extraordinarily thin. Vaiont Dam is 265 meters high, but only 22.7 meters thick at its base. In comparison, Hoover Dam is 221 meters high and 201 meters thick at its base and has a partial arch effect. In India, Idduki dam is known as Concrete arch dam, situated in Kerela ( Fig. 31.8).

Fig. 31.8. Concrete Arch dam (Idukki dam). (Source: http://tourmet.com/wp-content/uploads/2013/05/215-Idukki-Arch-Dam1-idukki.jpg)

31.6 Buttress Dam

Buttress Dams are made from concrete or masonry. The dam is supported at the downstream face by triangular shaped walls, called buttresses, at a suitable interval. They resist the force of the reservoir water trying to push the dam over. The buttress dam was developed from the idea of the gravity dam, except that it uses a lot less material due to clear spaces between the buttresses. Like gravity dams, they are suited to both narrow and wide valleys, and they must be constructed on sound rock, Fig. 31.9 shows buttress dam in Arizona.

Fig. 31.9. Bartlett Dam in Arizona is an example of a reinforced concrete, multiple arch and buttress dam; it consists of 10 arches, nine buttresses and two gravity wing dams. (Source: http://www.teachengineering.org/view_lesson.php?url=collection/cub_/lessons/cub_dams/cub_dams_lesson02.xml)

31.7 Embankment Dam

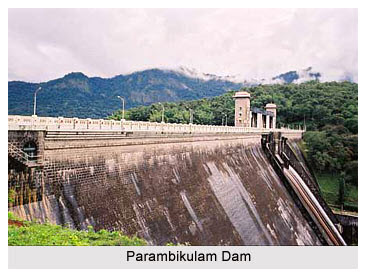

Embankment dams are mainly made from natural materials. The two main types are earthfill dams and rockfill dams. Earthfill dams are made up of compacted earth, while rockfill dams are made up mainly from dumped and compacted rockfill. The materials are usually excavated or quarried from nearby sites, preferably within the reservoir basin.

A cross-section (or slice) through an embankment dam shows that it is shaped like a bank, or hill. Most embankment dams have a central section, called the core, made from impermeable material to stop water passing through the dam. Clayey soils, concrete or asphaltic concrete can be used for the core.

Fig. 31.10. Embankment dam (Parambikulam dam, India). (Source: http://www.indianetzone.com/33/parambikulam_dam_kerala.htm)