Site pages

Current course

Participants

General

Module 1. Introduction to Theory of Machine

Module 2. Planar Mechanism

Module 3. Velocity and Acceleration Analysis

Topic 4

Topic 5

Topic 6

Topic 7

Topic 8

Topic 9

Topic 10

Lesson 22. BELT, ROPS AND CHAIN DRIVE

22.1 INTRODUCTION

A belt transmits power from one shaft to another by means of pulleys. Belts are one of the commonest and cheapest sources of power transmission. Power transmission through belts, rops and chains are achieved by specifically designed system. The pulleys may rotate in same or opposite directions depending upon the type of arrangement. The factors which play important role in designing belt drives are speed of shafts (driving and driven), shaft layout depending upon available space, type of application and power to be transmitted. The material of belt may be leather, cotton or fabric or rubber. Leather belts are made most widely used material for making belts. The belts are cleaned from time to time so that they remain dust free. The cotton belts are generally cheaper than leather belts and can be used in more hot and humid climate. They find applications is conveyors, hoist and machinery items. Rubber belts are quite flexible in nature and are therefore used in paper mills and saw industry.

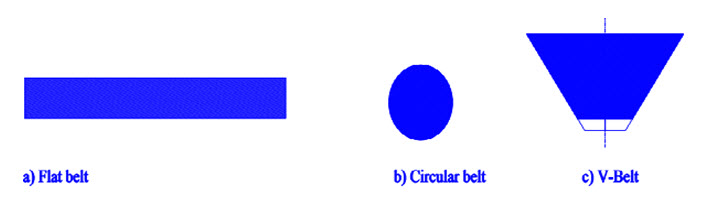

Fig 5.1 Types of belts

Belts may be flat, V- or circular cross-section. Belts find application in flour mills, power machines and electrical generators. Belt drives are simple to construct, require less maintenance and hence economical to use, are robust and are generally efficient source of power transmission. The major disadvantage of belt drives are slippage, and creep. Belts should be cleaned from time to time for best output.