Site pages

Current course

Participants

General

Module 1

Module 2.

Module 3.

Module 4

LESSON 12. Adjustment and maintenance of disk harrows

1. Introduction

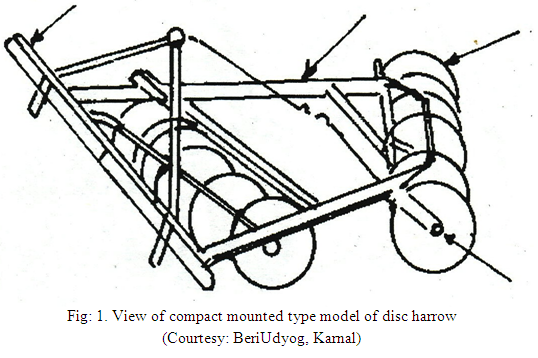

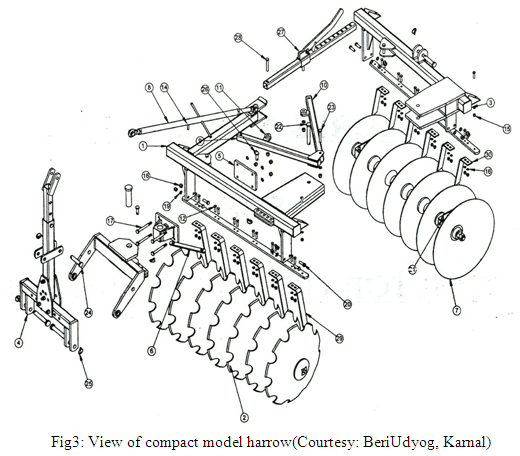

Disc harrow is secondary tillage equipment designed for harrowing / land preparation of rough soil (Secondary tillage/ finer operation). It is generally used for breaking the clods and partially inverting the soil. Regular and satisfactory operation together with economic and long lasting use of the implement depends on the compliance with instructions provided by the manufacturers.Thoroughly read the instruction manual before proceeding with the various operations and maintenance.

2. Adjustments in disc harrow

a) Adjustment before use:

1. Before mounting of disc harrow make sure that all nuts & bolts are properly tightened.

2. Also determine soil and trash conditions of the field and make the preliminary adjustments as discussed below:

- Disc gang angle adjustment: - Gang angle (Angle between two gangs) ranges from 0° to 50°. The angle can be increased for better penetration in dry soil while it should be reduced to avoid plugging in wet soil.

- Disc harrow leveling: - To eliminate uneven penetration and side draft, leveling is done by means of top link& bottom adjustable link. While tractor pulls to right the rear gang should be lowered a little. When the tractor pulls to the left the rear gang should be raised.

- Scrapper adjustment: - The scrapper can be adjusted by loosening the bolts atthe scrappers clamp.

- Depth control: - The depth at which the implement is required to work is controlled hydraulically by raising or lowering the left control lever.

- Disc harrow penetration:- Factors affecting disc harrow penetration are:-

- Angle of the gangs

- Weight of the harrow

- Disc diameter

- Disc sharpness (Blunt disc increases the draft considerably, check the disc sharpness)

- Angle of hitch

b) Attaching the harrow to the tractor

- Place the harrow duly leveled on the flat piece of land.

- Reverse the tractor to the harrow (Do not drag the harrow up the tractor).

- Attach the left arm of the tractor to the harrow first.

- Attach the central top link/ arm to the harrow. To attach, turn the screws on both side an equal length. If the arm is too short or too long, turn the screw to adjust both at the same time until aligned with the hole on the central arm.

- Attach the lower right arm; turn the screw until the mounting pin is at the same level as the hole on the tractor arm. If the gap between the hole and mounting pin is too close or too distant turn the control arm in or pull it away to an appropriate distance. User may have to adjust both height and distance at the same time. When the hole attractor arm and mounting pin are even, insert the pin in the hole and lock it with the lynch pin.

- After attaching the harrow, lift it and adjust the control arm parallel to the ground. When you looked from both rear or sideways the discs should all the touching the ground uniformly.

3. Operational guidelines for disc harrow

Instructions for the driver

- When Disc harrow is ready for use don't stand between disc harrow & the tractor.

- Properly fit the three point linkage as mentioned above & lock with lynch pin.

- In case of scrapper touching the discs, loosen the scrapper bolt and readjusts the scrapper.

- Never turn the tractor to the right or left when the harrow is engaged in the soil.

- Never reverse the tractor when the harrow is engaged in the soil.

- To get good results from the harrow, disc should be replaced when its diameter is reduced by 5" (125mm) from its original size.

Field operation:

a) Lift the harrow on turning for effective independent breaking of soil.

b) Adjust internal/ external check chains to obtain implement swing range within 50 mm (2") when raised.

c) Always maintain the correct tyre pressure to avoid wheel slippage.

d) Adding of wheel weights/water ballasting or combination of both is recommended when excessive rear wheel slippage is experienced.

e) Always set hydraulic levers correctly for draft and position control operation.

The following settings are necessary to ensure that uniform working depth is maintained:

i) Side draft: The offset disc harrow will trail correctly behind the tractor provided the side thrust of the front gang is equal to that of rear. In case it is different there will beside draft. To set it correctly the gang angle should be changed

ii) Severe side draft: In case of severe side draft the cutting depth of rear disc gang should be increased or decreased with the help of tractor top link. For instance when tractor pulls to right, lower the rear gang and when tractor pulls to left, raise the rear gang.

f)Warning for driver:

- Before harrowing check all nuts & bolts of the harrow disc.

- Before harrowing with harrow disc take care that nobody stands near it.

- Be vigilant about the tree roots and stones. Don’t harrow on stony soil.

- Tractor should be in first high or fourth low gear.

- Do not allow anyone to come across the harrow.

- Lift the disc harrow on every turn.

- Lift the harrow before approaching the road.

g) Precautions during transportation:

- When transporting the harrow, shorten up top link to minimum length.

- Set hydraulic lever in top raised position and lock levers.

- Maintain the speed to avoid jump.

- Watch while overtaking on road.

- Always use SMV (Slow Moving Vehicles) symbols.

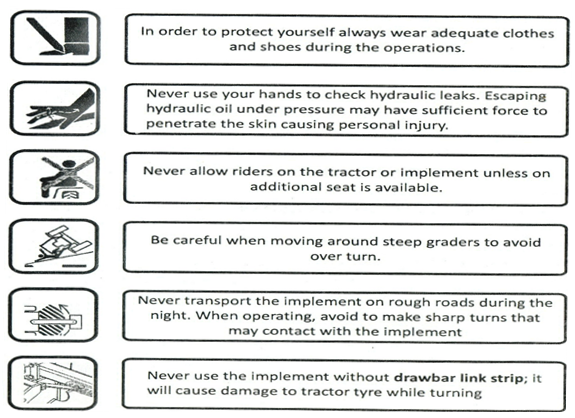

h) Safety symbols:

Safety symbols on disc harrow: - Ensure that above safety symbols are marked on the harrow for caution of operation.

4. Maintenance of disc harrow

a) Maintenance instructions

If the harrow is used in the stony land then maintenance of disc harrow also increases.

- If the soil has entered the grease nipple, then change the nipple.

- If disc harrow is new, then after initial working of first two hour, tighten all nuts & bolts.

- After every fifty hours of use, grease all greasing points with grease gun and tighten all nuts & bolts.

- After fifty hours of use, open the bracket spool of disc harrow & clean with diesel oil & pump in new grease.

b) Storage of machine after work

- Wash the disc harrow after work.

- Replace the worn out nuts & bolts.

- If the disc harrow has to remain unused for long time then clean it & apply a layer of used oil for rust prevention.

c) Lubrication

Please take care that high quality grease is used in spools.

5. Trouble shooting chart for disc harrow

|

Sr. No. |

Possible cause |

Possible remedies |

|

A. |

Side draft |

|

|

1 |

Disc not running level. |

Adjust using leveling lever |

|

2 |

Gangs improperly angled |

Set the gang angle properly |

|

3 |

Too much left hand offset |

Swing the hitch to the left |

|

B. |

Excessive field slippage |

|

|

1 |

Tractor overloaded |

Reduce angle, reduce depth |

|

2 |

Not enough tractor ballast |

Add wheel weight or liquid in tyres |

|

C. |

Not filling the furrow |

|

|

1 |

Too much left hand offset |

Swing hitch to the right hand |

|

2 |

Tractor wheel running in furrow enlarging it. |

Drive the tractor in unworked ground |

|

3 |

Discs too far from furrow |

Keep the left front discs in furrow |

|

4 |

Rear gang set wrong , laterally |

Move the rear gang right or left. The left rear should be centered in the space between left front discs. |

|

D |

Poor penetration |

|

|

1 |

Hard ground |

Swing hitch to the right. Increase angle in front and rear gang. |

|

E |

Disc unsteady |

|

|

1 |

Too much angle in gang |

Reduce gang angle |

|

F |

Gang plugging |

|

|

1 |

Field too wet |

Disc at shallow depth for first pass to speed up drying process |

|

2 |

Gang set in maximum angle |

Reduce the gang angle |

|

3 |

Not using scrappers |

Install scrappers |

|

4 |

Scrappers worn out or not set properly |

Replace worn ones, Adjust scrappers close to the disc |

|

5 |

Discing too deep in damp soil |

Reduce penetration of harrow |

References:

Jain S. C. and Philp Grace (2003) Farm Machinery an approach. Book Pub. Standard Publisher and distributor, New Delhi

Wadhwa D.S., Dhingra H. S. &Santokh, Singh Field operation and maintenance of tractor and farm machinery (FMP-301), laboratory manual by, Department of Farm Machinery and Power Engineering, PAU Ludhiana

Service and maintenance manual of Mould Board Plough, BeriUdyogKarnal (Haryana)