Site pages

Current course

Participants

General

Module 1

Module 2.

Module 3.

Module 4

LESSON 13. Adjustment and maintenance of seeding and planting equipment

Seeding equipment / implement: It is a machine which is used for sowing of seed at required row to row spacing and depth.

Planting equipment / implement: It is a machine which is used to plant the seed at required row to row and plant to plant spacing and depth.

1. Seed cum fertilizer drill cum planter:

This machine can be used for sowing grains like wheat, maize,groundnut, peas, cotton, sunflower etc. The planting discs plates for different crops can be changed without dismantling the seed hoppers main shaft. Fertilizer can be used simultaneously according torequirement. Furrow openers have ben mounted on frame using U Clamps. These can be replaced with ridgers and bed shapers for converting it bed planter.(Fig: 1.)

2. Adjustments in MulticropPlanter

a) Furrower openers and ridgers

Furrow openers can be adjusted by removing or raising few furrow openers with shanks according to the number of rows and spacing in different crops to be raised on the top of the raised beds (Fig: 2.) .As shown in Figure: 3, three ridgers have been provided to make two beds in a single pass. Most of the farmers have tractors in the range of 35-45 HP and 3 ridgers caneasily be pulled by these tractors.Height of the beds in wheat varies from 15to 30 cm and it can be further adjusted. Whereas, the width of furrow and top of the bed generally remain 30 cm and 37 cm respectively. However, it can be varied from 20to 40 cm by adjusting the wing width. (Fig: 4.)

b) Adjustment of the bed shaper

Bed Shaper should also be adjusted in the upward and downward position for shaping the bed. Just loosen the bolt and lift the shaper towards the upward position if the bed little higher is required than higher the nut and bolt again as well as for a bed at the lower position, loosen the nut and bolt again and shift the shaper to the downward direction and tighten thenuts and bolts as shown in Fig: 5.

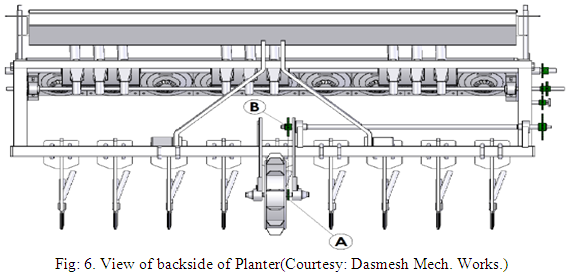

c) Seed metering speed adjustments: As shown in Figure 6 & 7 select appropriate, select appropriate combination of gear / sprockets for getting desired speed of rotation of seed &fertilizer metering shafts.

Figure shows following processes:

|

A |

11 Teeth sprocket |

|

B |

20 Teeth sprocket |

Figure shows following process:

|

C |

28 teeth sprocket |

|

D |

11Teeth sprocket for seed box |

|

E |

15 Teeth sprocket for fertilizer box |

|

F |

15 Teeth idle |

|

G |

Transmission chain |

d) Seed rate adjustments:

a) In order to adjust the inclined plates we have to put washer between the nylon plate and housing on the shaft so that the face of plate should not have any gap between the face of housing.

b) The function of press plate is to provide proper pressure on the ring.

c) Adjust the nut as per required pressure on the ring. (Fig: 8.)

Increase and Decrease the flow of seed:

To increase the flow of seed, lift the seed box in the upward direction, and to decrease the flow shift the seed box in the downward direction (as shown in Fig: 9.).

Seed Metering:

i) For Wheat:

a) Use the 16 no`s spoon plane plate.

b) As given in Fig: 10. sprocket selection is as under:

|

Position |

|

|

C |

28 Teeth sprocket |

|

D |

11 Teeth sprocket for seed box |

|

E |

15 teeth sprocket for fertilizer box |

|

F |

15 teeth idle |

ii) For soyabean:

a. Use the 8 no`s spoon inclined plate no. “0”.

b. As given in Fig: 11.sprocket selection is as under:

|

Position |

|

|

C |

28 Teeth sprocket |

|

D |

15 Teeth sprocket for seed box |

|

E |

15 Teeth sprocket for fertilizer box |

|

F |

15 Teeth idle |

iii) For maize, chick pea and bengal gram:

-

Use the 8 no`s spoon inclined plate no. “20”.

-

As given in Fig: 12.sprocket selection is as under:

|

Position |

|

|

C |

11 Teeth sprocket |

|

D |

15 Teeth sprocket for seed box |

|

|

|

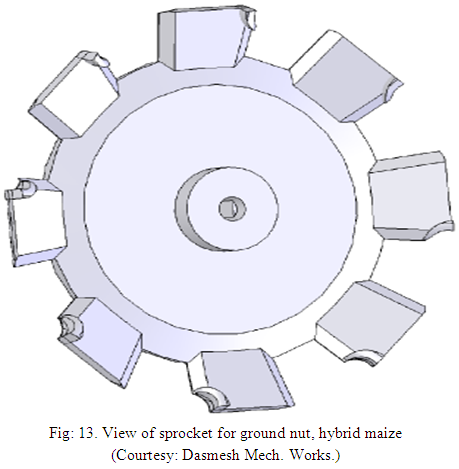

iv) For ground nut, hybrid maize:

a) Use the 8 spoon inclined plate no. “30”.

b) As shown in Fig: 13. sprocket selection is as under:

|

Position |

|

|

C |

15 Teeth sprocket |

|

D |

28 Teeth sprocket for seed box |

|

E |

15 Teeth sprocket for fertilizer box |

|

F |

15 Teeth idle |

e) Calibration of seeding equipment:

Before taking the seed drill or crop planter into the field it is very essential to calibrate its metering mechanism to obtain the required seed rate per hectare or per acre of the crops to be planted. The following steps are followed in calibration of the seed drill:

1.Jack up the seed drill and mark a reference point on the ground wheel.

2.Measure the diameter of ground wheel. Let us say it is “D”meter.

3.Measure the working width of the drill or planter and let us say it is ‘W’ meter.

W = n x d

Where,n = no. of tynes

d = distance between two tynes (m)

4.Workout the circumference of ground wheel ( x D)

5.We assume that the planter or drill has to be used in a field having length x breadth as 100 x 100 sq. m.

6.Workout the revolution of the ground wheel required to travel a distance of 100 m.

= 100/ (π x D)

= X (say)

7.Now give the 'X' revolution to the wheel and collect the seeds from all the furrow openers separately. Weigh all the collected seed separately. It should be noted that there should not be large variation in the weight of the seed collected fromthe different furrow openers. Let's say the total weight of the seeds collected from all furrow openers is 'P' kg

8.Workout the total no. of revolutions required to cover one hectare of field:

100 x 100

= ------------------------- = Y (say)

π xD x W

9.Allow 10% slippage of groundwheel under actual field conditions and recalculate ‘Y’

10.Workout the total amount of seed for ‘Y’ revolutions

For ‘X’ revolutions ‘P’ kg of seed are collected

P

Therefore, for Y revolution = -------------------- = G (kg)

X x Y

Thus, by substituting the value of ‘P’ and ‘X’ revolutionswe can obtain the quantity of seed to be sown in the field. Thus, the process is repeated by suitably adjusting the lever on the indexing device till we get the desired seed rate, recommended for a particular crop under planting or sowing.

3. Planting operations:

- Seed should be of good quality and free from dirt and dust.

- Fertilizer should not have clods. Clods should be properly broken to uniform size for free flow of fertilizer.

- All the nuts and bolts, and springs should be thoroughly checked, defective parts should be replaced and nuts/bolts properly tightened.

- Seed and fertilizer boxes should be thoroughly cleaned.

- Multi crop rings shaft should move freely, otherwise the plates can damage the seed.

- Seed plates should be thoroughly cleaned and blocked if any, must be removed.

- Ensure that plastic pipes do not have excessive bend. This will block the free flow of seed and fertilizer in tubes.

- Chain sprocket of metering mechanism should be properly aligned. Appropriate tension in the chain may be kept for free movements of seed and fertilizer metering shafts. If there is any noise during operation, stop the machine and check it.

- Furrow openers should be fitted on the frame according to the requirement (row to row distance) of the crop. There should be no crossing or twisting of furrow openers.

- Fill the seed and fertilizer boxes and calibrates the machine. Ensure that the seed drill is set at desired seed and fertilizer rates. This will ensure proper metering of seed and fertilizers and result in excellent germination, good crop stand and higher yield.

4. Safety precautions:

a) Precautions for use of inclined plate planter

- Field should be leveled and well prepared before operation.

- Do not allow drying up of the upper soil layer before sowing, otherwise, seedwill have to be placed deep and it will affect germination.

- Mechanical weeding or interculture with this machine (after making minoralterations in the positions of its tines) is possible in the standing crop.

- Special care should be taken regarding depth of seeding; otherwise there maybe problems in seed germination.

- Attack of termites may be another problem in sandy areas; hence, specialattention or precaution should also be taken in this regard.

- Care should be taken by the farmers to balance the machine before starting sowing.

- All inclined plate seed boxes should be in straight position.

- Depth of sowing should be properly adjusted by depth control wheel.

- Seed rate will be increased & decreased by changing the sprocket sets.

b) Precautions for use of raised bed planter

- Field should be leveled and well prepared before making beds.

- Beds are made well in advance and field irrigated to encourage germination of weeds before sowing and then germinated weeds can be controlled either mechanically by reshaping the beds or during operation or with the spray of non- selective herbicide glyphosate in rice–wheat cropping sequence and broad leaf weeds in sandy or sandy loam soils with other crop rotations can easily be controlled.

- Do not allow drying up of the upper soil layer before sowing otherwise seed will have to be placed deep and it will affect germination.

- Mechanical weeding or interculture with this machine (after making minoralterations in the positions of its tines) is possible in the standing crop, if it has been shown in two rows/ bed.

- Special care should be taken regarding depth of seeding; otherwise there may be problems in germination.

- Attack of termites may be another problem in sandy areas; hence, special attention or precaution should also be taken in this regard.

- Sometime due to imbalance of machine attached with tractor or present shape of wings of ridger, soil layer on one side top of alternate beds is formed which may hamper seed germination. So care should be taken by the farmers to balance the machine to remove this soil layer or to modify the wings by getting these cut at outer edges.

5.Maintenance and Repair of Seeding Machines:

A well maintained and properly adjusted seeding machine gives trouble free service for a long time. It also helps in timely completion of operations. The following important points may be kept in mind for the maintenance and repair of various components of the seeding machines.

a) Seed and fertilizer boxes

The boxes should be thoroughly cleaned as these may rust very fast due to environmental moisture. This will damage the boxes and machine will not be useful for the next crop sowing season. The boxes must be cleaned asunder:

- Raise the machine above ground so that the drive wheels move freely.

- Remove seed and fertilizer from boxes.

- Open the flow gates of seed and fertilizer cups.

- Rotate the drive wheel till the seed and fertilizer from different seed and fertilizer cups areemptied. Clean the boxes and cups with the help of a cloth or brush.

- Wash the machine rollers/seed/fertilizer boxes with diesel to avoid rusting.

- Apply lubricating oil at appropriate places (bushes and sides of metering rollers).

b) Drive/ power transmission system.

- Drive wheel should move freely. If it is jammed, then apply grease or put oil in itsbushes. If axle of wheel is bent or worn out, replace it.

- Drive wheel should be round, if it is bent then repair it.

- Sprockets of drive wheel and feed shafts (seed and fertilizer boxes) should be properlyaligned.

- All sprockets should be properly tightened on their shafts so that these may not move freelyon these shafts.

- Feed shafts should move freely. If these are jammed due to rusting, then clean and applylubricating oil/grease in the bushes.

- Bent drive shafts should be repaired or replaced.

- Seed and fertilizer boxes should be thoroughly cleaned for free movement of feed shafts.

- Chain and idler sprocket should be properly tightened so that proper chain tension ismaintained and mechanism moves freely.

- Worn out parts, loose, broken and worn out bushes should be replaced.

c) Seed metering mechanism

Usually Inclined plate type seed metering mechanism is used in this seeding machine.

It should be repaired and maintained as under.

- Take the seed out of the small seed boxes by opening the lower flow gates.

- Remove the nuts/bolts of the ring from the base plate.

- Remove the ring from the shaft.

- Check the rings & spoons attached to the rings.

- During refitting of rings, it must be ensured that all the rings are at equal distance in the seedcups. If distance is different, then adjust it by losing the bolt on the base plate bush to achieve equal distance.

- Complete system should move freely and rotate the sprocket till appropriate seed rate achieved from all the rings.

d) Fertilizer metering mechanism

In fertilizer metering mechanism, fertilizer settles on its parts due to environmental moisture whichmay cause obstruction in free and uniform flow of fertilizer. Large particles also cause hindrance in the mechanism. Therefore, this system requires special attention as follows:

- After seeding a crop, fertilizer should be removed from the box and whole system should becleaned with the help of brush or cloth.

- If the system is jammed due to corrosion and rusting, cell of the fertilizer feeder must beremoved and cleaned.

- All the plastic tubes/ pipes should be properly open.

- Lever on both side of the fertilizer box should move easily. This helps in proper metering offertilizer.

- Tighten all nuts and bolts of the mechanism.

- Seeds and fertilizer tubes

These are mostly plastic tubes connected to seed/fertilizer cups and their lower ends are connected to seed boots.

- Tubes should be connected to seed/fertilizer cups with the help of clamps so that these maynot come out during field operation.

- Tubes should be protected from bending and breakage.

- Old/bent tubes should be replaced.

- Excessive bend in the tubes should be avoided otherwise the bend will cause obstruction infree flow of seed/fertilizer and results in non-uniform application of fertilizer in the field.

f) Furrow openers

Furrow openers are attached to main frame with the help of U-bolts. The furrow openers wear out or twist very fast. Therefore, these should be repaired frequently. The worn-out ones should be removed /replaced as and when required.

g) General

- All the components of the machine should be painted.

- Machine should be protected from rain, dirt and dust etc. during its storage.

- Moving parts should be greased / oiled at regular intervals so that the machine gives a trouble free service for a long time.

- Users training will lead to improvement in the performance of the machines.

References:

Jain S. C. and Philp Grace (2003) Farm Machinery an approach. Book Pub. Standard Publisher and distributor, New Delhi

Wadhwa D.S., Dhingra H. S. &Santokh, Singh Field operation and maintenance of tractor and farm machinery (FMP-301), laboratory manual by, Department of Farm Machinery and Power Engineering, PAU Ludhiana

Operation and maintenance manual of seed drill, Dasmesh Mechanical Works Sangrur.