Site pages

Current course

Participants

General

Module 1

Module 2.

Module 3.

Module 4

LESSON 15. Adjustment, operation and maintenance of harvesting equipment

Harvesting equipment or implement: Harvesting equipments are the machines which are used for cutting and harvesting the crop to separate the grain from straw.

Harvesting is the process of cutting and collecting the mature crop from the field. The goal of good harvesting methods is to maximize grain yield, and to minimize grain damage and quality deterioration.

Timeliness of harvest is of prime importance. During harvesting season, often rains and storms occur causing considerable damage to standing crops. Rapid harvest facilities extra days for land preparation and earlier planting of the next crop. The use of machine can help to harvest at proper stage of crop maturity and reduce drudgery and operation time.Considering these, improved harvesting tools, equipment, combines are being accepted by the Farmers.

There are various designs of tools and equipment used for harvesting the crops and threshingit separately. Sickles, hand tools and reapers for grain crops and diggers for tuber crops and

Rhizomes, operated with different power sources are used. Combine harvesters, both tractorsmounted and self-propelled, are being very widely used for different grain crops. Functionalrequirements and principles of working of tools and equipment for harvesting are given below:

Harvesting Tools and Equipment

Crops are harvested after normal maturity with the objective to take out grain, straw, tubersetc. without much loss. It involves cutting / digging / picking, laying, gathering, curing, transport and stacking of the crop. In case of cereals like wheat and paddy the plants are straight and smooth and ears containing grains are at the top whereas most of oilseed and pulse crops have branches, which create problems' in harvesting by manual or mechanical means. As per Bureau of Indian Standards the cutting and conveying losses should not be more than 2 per cent.

1. Traditional method of harvesting

The harvesting of crops is traditionally done by manual methods. Harvesting of major cereals, pulse and oilseed crops are done by using sickle whereas tuber crops are harvested bycountry plough or spade. All these traditional methods involve drudgery and consume longtime.

2. Mechanical harvesting equipment

Different type of mechanical harvesting tools / equipment, suitability for crops and their limitations are given below:

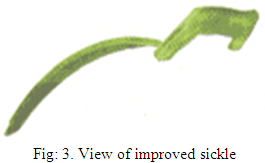

(a) Serrated blade sickle:

It has a serrated curved blade and a wooden handle (Fig: 3.).The handle of improved sickle has a bend at the rear for better grip and to avoid hand injury during operation. Serrated blade sickles cut the crop by principle of friction cutting like in saw blade. The crop is held in one hand and the sickle is pulled along an arc for cutting. Cutting of crop close to the ground is possible with modified handle. Energy requirement is 80-110 man-h/ha. It can be usedeffectively for harvesting of wheat, rice and grasses.

(b) Reapers

Reapers are used for harvesting of crops mostly at ground level. It consists of crop-row divider, cutter bar assembly, feeding and conveying devices. Reapers are classified on the basis of conveying of crops as given below:

i) Vertical conveying reaper windrower

It consists of crop row divider, star wheel, cutter bar, and a pair of lugged canvas conveyor belts. This type of machine (Fig: 3.) cut the crops and conveys vertically to one end and windrows the crops on the ground uniformly. Collection of crop for making bundles is easy and it is done manually. Self-propelled walking types, self-propelled riding type and tractor mounted type reaper-windrowers are available. These types of reapers are suitable for crops like wheatand rice. The field capacities of these machines vary from 0.20-0.40 ha/h.

ii) Horizontal conveying reapers

This type of reapers is provided with crop dividers at the end, crop gathering reel, cutter bar and horizontal conveyor belt. They cut the crop, convey the crop horizontally to one end and drop it to the ground in head-tail fashion. Collection of crop for making bundles is difficult. This type of reapers is tractor mounted and suitable for wheat, rice, soybean, and gram. Performance of reapers with narrow-pitch cutter bar is better for soybean and gram crops.

iii) Bunch conveying reapers

This type of reapers are similar to horizontal conveying reapers except that the cut crop iscollected on a platform and is being released occasionally to the ground in the form of abunch by actuating a hand lever. Here, collection of crops for making bundles is difficult.

Bullock drawn and tractor-operated models are available and they are suitable for harvestingwheat, rice and soybean crops.

iv) Reaper binders

The cutting unit of this type of reapers may be disc type or cutter bar type. After cutting, thecrop is conveyed vertically to the binding mechanism and released to the ground in the formof bundles. Self-propelled walking type models are available but these are not popular due tohigh cost of twine. Reaper binders are suitable for rice and wheat.

(c) Strippers

The design of a tractor front mounted stripper is available for collection of matured grassseeds from the seed crops. It consists of a reel having helical rubber bats which beat the grassover a sweeping surface where the ripened seeds get detached and the seeds are collected inthe seed box.

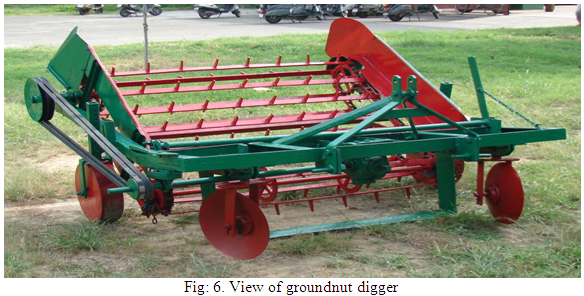

(d) Diggers

The designs of groundnut and potato diggers of animal drawn and tractor operated types areavailable. The digging units consist of V-shaped or straight blade and lifter rods are attachedbehind the share. These lifter rods are spaced to allow the clods and residual material to dropwhile operating the implement. The plant along with pods/tubersis collected manually. (Fig: 6.)

(e) Combines

Various designs of combine harvester having 2 to 6 m long cutter bar are commerciallyavailable. The function of a combineharvester is to cut, thresh, winnow and clean grain/seed. It consists of header unit, threshingunit, separation unit, cleaning unit and grain collectionunit. The function of the header is tocut and gather the crop and deliver it to the threshing cylinder. The reel pushes the straw backon to the platform while the cutter bar cuts it. The crops are threshed between cylinder andconcave due to impact and rubbing action. The threshed material is shaken and tossed backby the straw rack so that the grain moves and falls through the openings in the rack onto thecleaning shoe while the straw is discharged at the rear. The cleaning mechanism consists oftwo sieves and a fan. The grain is conveyed with a conveyor and collected in a grain tank. (Fig: 7.)

3.Methods and equipments for harvesting major crops:

Harvesting of crops like paddy and soybean has to be done carefully as the matured grains easily detach from the ear heads/pods and, therefore, cannot be harvested by fast working tools or machines. Bengal gram, green gram, lentil is to be harvested at ground level.

Oilseed crops pose different type of problems to engineers for mechanization of their harvesting.

Safflower is a spiny crop and difficult to harvest even manually. In case of sunflower, harvesting is simpler as only flower heads are to be collected. In sesamum crops, pods containing seeds are attached to the main stem and they are mostly raised by broad casting. This also needs gentle handling. Farmers follow different methods for harvesting of rapeseed/mustard and pigeon pea. Mostly, farmer harvest these crops at branch level, but small farmers harvest these crops at ground level.

Harvesting of root crops involves digging, shaking to remove adhering soil, windrowing or stacking and picking. A good root crop harvester should give maximum recovery and cause minimum damage to pods or tubers.

The harvesting methods followed by farmers for major crops are as follows:

a) Cereal crops

Wheat and Rice: Harvesting of wheat & rice crop is traditionally done by using local sickle.

Improved serrated blade sickles are also in use. The following machines are available for efficient harvesting of these crops.

- Reaper binders

- Self propelled walking type reaper

- Combine harvesters

- Tractor front and rear mounted reapers

Sorghum: Harvesting by local sickle is the traditional practice followed by the farmers. Suitable

Machines are not available for harvesting this crop. However, combine harvesters are in use in advanced countries.

Maize: The traditional practice is to collect the matured cobs manually. Grain combines equipped with corn-head snapping unit are also available.

Pulse crops

Bengal gram: Harvesting by local sickle is the traditional practice. Improved serrated blade sickles are also in use. The performance of narrow pitch cutter bar with horizontal conveyor is better than other types of available reapers. Combines with floating cutter-bar are in use in advanced countries.

b) Pigeon pea: This crop is traditionally harvested at ground level by using a chopper or local sickle. No suitable machine for harvesting this crop is available in the country. Crop stems are being used by farmers for domestic use.

Urad, Moong and Cowpea: These crops are traditionally harvested by using local sickle.

Improved serrated blade sickles are also in use.

c) Oilseed crops

Groundnut: Digging of crop with country plough and blade hoe at proper soil moisture level and manual pulling and gathering of pods using hand hoe is common practice.

Animal drawn and tractor operated diggers and digger windrowers are improved implements developed for groundnut harvesting. The blade harrow is widely used for digging of groundnut crop in Gujarat. TNAU, CIAE and CTAE, designs are some of the improved animal drawn groundnut diggers.

4. Adjustments in harvesting equipment:

a) Combine harvester adjustments:

-

Adjust machine speed. Check the machine speed to see that the combine is operating at the recommended revolutions per minute. The manufacturer's operator manual will give the basic speed of machine. This may be given as beater shaft speed, engine speed at rated r.p.m, blower speed, threshing cylinder speed etc.

-

Adjust cylinder concave clearance and cylinder speed. These adjustments have a great effect on the rack and shoe losses in the combine over threshing breaks up the straw and cause the rack and shoe to be over-loaded. Adjustments are provided for varying the speed of cylinder to suit the kind of crop being harvested. Too slow cylinder speed or too wide concave clearance may result into back feeding at cylinder. A compromise between cylinder speed and concave clearance should be maintained. These are given in Table 4.3 for guidance.

Basic machine settings

|

Type of crop |

Drumspeed |

Concave clearance |

Sieves |

Straw walker |

|

|

(rpm) |

|

|

(rpm) |

|

Wheat |

900-1000 - |

Front - 15mm |

Upper - 16 -19mm |

200 |

|

|

|

Rear - 7mm |

Lower - 6 to 8mm |

|

|

Paddy |

600-800 " |

Front - 17mm |

Upper - 16 -19mm |

180 |

|

|

|

Rear - 14mm |

Lower - 5 to 6mm |

|

|

Sunflower |

*400-650 |

Front - 17mm |

Upper-12.5-19mm |

200 |

|

|

|

Rear - 14mm |

Lower- 8mm Øhole- |

|

|

Soybean |

*250-600 |

Front - 15mm |

Upper - 16 -19mm |

200 |

|

|

|

Rear - 11mm |

Lower- 8mm Ø hole |

|

|

Mustard |

*450-700 |

Front - 10mm |

Upper - 16 -19mm |

200 |

|

|

|

Rear - 5mm ' |

Lower - 4 to 5mm |

|

|

Gram |

*450 - 700 •. |

Front - 15mm |

Upper - 16 -19mm |

200 |

|

|

|

Rear - Ilmm |

Lower- 7 to 10mm |

|

Source: Operator's Manual of Swaraj 8100 Combine

* Speeds can be obtained using special reduction gear box

3.Adjust cutter bar height: The height of cut should not be lower than required otherwise too much material will overload the rack and on too high heads or ear of grain will be left in the field.

4.Reel adjustment: 'The reel may be adjusted to speed, height and position forward or rearward.

Reel speed = 1.25 x travel speed

Optimum value of reel index should be 1.1 to 1.25% for minimum cutter bar loss.

Reel height for different crop condition:

(a) For medium and short crops: adjust reel approx. 100mm above the cutter bar and for enough forward.

(b) For taller crops: set reel back and raised so the bats run close to the top of grain.

(c) For down crop: adjust the reel to a lower and forward position.

5. Cutter bar adjustment

(a) Guard alignment

(b) Knife clips

(c) Wearing plates

(d) Sickle register

If these parts become loose or worn, the knife will chew and tearthe crop instead of cutting it. This will also cause excessive shattering of ripe crops.

Requirements of field and crops for harvest by mechanical reapers or windrowers.

The following criteria must for successful use of mechanical harvesting equipment.

- Field must be fairly level without undulations to facilitate smooth operation and uniform stubble length.

- Water control in rice field is essential to ensure that the fields are drained and are relatively dry at harvest time.

- For small reapers and binders, plants must be grown in rows.

- Field efficiency of harvesting machines is high in large fields.

6. Adjust forward speed. Ground speed should not be changed by using the throttle. The engine should be run at recommended speed. Forward travel speed should be adjusted by shifting gears and by variable pulleys. Driving too fast increases rack losses due to over loading the combine and also increase shattering and uneven height of cut.

7.Adjust the cleaning sieves and fan blast. Poor adjustment in the cleaning area· of the combine will also cause grain loss. These adjustments and the operating loss or trouble they will cause are as below: '

(a)Chaffer opening adjustment.The lips may be raised or lowered to regulate the size of openings on the chaffer. The opening should be large enough to allow the grain to work through the chaffer before it passes over two third of its length.

(b)Chaffer height adjustment. In some combines the rear of the chaffer can be raised to move the material uphill thus keeping it longer on the chaffer and increasing cleaning action. But when this is done the opening should be kept small.

(c)Chaffer extension opening adjustment. The chaffer extension openings should be large enough to allow the un-threshed portion of the heads to pass through into the tailing trough. At the same time coarse material should be carried out of the machine.

(d)Chaffer extension height adjustment. The chaffer extension should be adjusted just high enough to prevent grain from being blown over and low enough to prevent clogging at the rear of the chaffer.

(e)The shoe sieve opening adjustment. The shoe sieve openings should be small enough to allow only threshed grain to pass into the grain auger.

(f)Blower adjustment. Correct speed adjustment of the blower is important to ensure a well balanced blast through the sieves. In general, the smaller the seed, less air blast should be and the lager the seed the greater the force of air blast should be.

(g) Tail board.Can be raised and lowered as necessary to prevent un-threshed material from being' carried out of the rear while still allowing the chaff to be blown out.

8. Troubleshootings in combine harvester

|

Problem |

Remedy |

|

Cutterbar |

It is absolutely necessary to stop the combine when working on or around the cutterbar. If it is necessary to work underneath, block the cutterbar upto avoid risk of accident. |

|

Poor cutting action |

1. Adjust knife registration. 2. Reset knife keeps. 3. Sharpen knife. 4. Straighten finger bar. 5. Replace damaged knife sections. 6. Remove build-up of foreign material from the cutterbar. |

|

Sudden knife blockage |

1. Remove foreign objects. 2. Replace misaligned cutterbar fingers. 3. Adjust tension of drive belt. |

|

Dirt and material built-up on divider points |

1. Set drives to higher position using the slide. 2. Renew cutter bar skids if necessary. 3. Adjust the reel further forward. |

|

Cutterbar lifts too slowly |

1. Check hydraulic oil level and fill up if necessary. 2. Have hydraulic oil pressure checked. |

|

Reel tending to stop |

Adjust slip clutch tension a little bit. |

|

Feed rake and cutterbar tending to stop |

Adjust jockey pulley of cutter bar V-belts clutch. |

|

Cutterbar dips at one end |

Loosen the securing bolts on the feeder house and adjust cutterbar mountings to level cutterbar. |

|

Cutterbar clutch will not disengage |

1. Check adjustment of cutterbar clutch belt guides. 2. Clean V-belt pulleys of cutterbar clutch. |

|

Uneven crop feed |

1. Adjust main table auger height to suit crop conditions. 2. Adjust reel tine position and reel speed. 3. Adjust feed rake chains to proper tension. |

|

Main table auger tending to stop or gets blocked |

Turn the main table auger back by the flights and remove foreign matter. |

|

Crop wrapping round the reel shaft ends. |

Adjust inner deflectors closer to cutterbar centre and possibly higher. |

|

Crop wrapping round the reel finger tubes. |

1. Raise the reel. 2. Set reel fingers more inclined to the front. 3. Adjust reel speed to match ground speed. |

|

Reel fingers fouling knife in lowest position |

Raise reel position by means of reel cylinder eye bolts. |

|

Reel dips at one end |

Check for equal adjustment of reel cylinder’s eye bolts. |

|

Too many stones being picked-up |

1. Reduce number of grain lifters, if fitted. 2. Do not cut unnecessarily low (lodged crops should be lifted with grain lifters). |

|

Slugging of drum |

1. Reduce drum-to-concave clearance 2. Increase drum speed in damp crops 3. Adjust basic settings of concave 4. Care for even feeding of crop to feed rake 5. Adjust main table auger further down 6. Check and have speed of main drive shaft adjusted 1140±5 rpm if necessary 7. Reduce ground speed as moisture level increases 8. Adjust spring-loaded cylinder for threshing mechanism drive power band belt stones and other foreign matter causing damage to threshing parts |

|

Stones and other foreign matter causing damage to threshing parts |

1. Clear stone trap frequently 2. Do not cut unnecessarily low on stony ground |

|

Irregular speed variations |

1. Correct the settings of the idler pulley and spring-loaded cylinder that controls the tension of the power band belt 2. Check engine (see engine problems) |

|

Poor threshing action |

1. Adjust concave closer to drum 2. Increase drum speed 3. Adjust basic setting of concave 4. Have worn or damaged threshing equipment repaired or replaced. 5. Adjust relative position of concave entrance and concave exit to match crop conditions 6. Use special threshing equipment if necessary. |

|

Unbalance |

1. Clean dirty threshing drum 2. Remove dust accumulations from belt pulleys 3. Have damaged rotor repaired |

|

Grain cracking |

1. Decrease drum speed 2. Increase drum-to-concave clearance 3. Adjust frogmouth sieves wider open 4. Adjust tension of elevator chains |

|

Excessive belt wear |

1. Engage combine drives with engine at slow idling speed and then bring the engine to full speed 2. Adjust belt tensioners |

Cleaning

|

Problems |

Remedy |

|

Uneven feed to sieves |

Clean preparation floor |

|

Knocking sieve pan |

1. Remove dirt accumulations from above cleaning fan housing 2. Retighten all bolts that secure the sieve pan 3. Tighten the components securing the sieves 4. Have sieve pan bearings replaced |

|

Excessive built up of material on frogmouth sieves |

1. Reduce drum speed 2. Adjust concave to drum clearance wider open 3. Open concave clearance at the rear 4. Adjust frog mouth sieves to somewhat closer gaps 5. Increase wind blast |

|

Dirty grain sample |

1. Increase wind blast 2. Set air Intake apertures to correct position 3. Decrease frog mouth sieves opening. 4. Decrease main frogmouth sieve opening, respectively 5. Have basic speed of machine checked and corrected I~ necessary (belt tension). |

Returns

|

Problem |

Remedy |

|

Excessive amount of chaff and short straw in returns |

1. Increase wind blast 2. Adjust frog mouth sieves to somewhat closer gaps 3. Reduce drum speed 4. Possibly change concave clearance at the rear. 5. Have basic speed of machine checked and correct if necessary |

|

Excessive amount of grain in the returns |

1. Adjust frog mouth sieves wider open 2. Adjust returns step floor |

|

Excessive amount of green stuff in the returns |

1. Lift cutterbar to highest possible position, the grain lifters should lift the crop out of the green stuff 2. Adjust rear end of frogmouth sieve to somewhat closer gaps |

Elevators

|

Problem |

Remedy |

|

Elevator obstructed |

1. Open elevator bottom flap to remove obstructing material. Open auger trough. Run combine with open flap until elevator and auger are clear. Tightly close elevator bottom flap and auger trough. 2. Possibly improvement by re-tensioning elevator chain. 3. Avoid material build-up and excessive tailings. 4. Adjust tension of the belt driving the elevators. |

Grain tank

|

Problem |

Remedy |

|

Grain tank recharge not functioning |

1. Adjust tension of V-belt 2. Readjust the drive and belt guides for the grain tank unloading augers 3. Bend misaligned auger flights |

Grain losses

|

Problem |

Remedy |

|

Grain losses |

Losses of grain may have different reasons. Therefore, always determine first where the losses occur. Checks combine for leakage losses. Check whether grain is lost where working parts join, especially check auger troughs, elevators etc. Extra care should be taken to check the working parts for good fitting when combining small seeds. Repair all leaks as necessary. Losses that are caused by overripe crops or poor weather conditions must not be taken for combine losses. Grain losses that are due to combining usually have four main causes: a) Losses of grain over the cutterbar b) Losses of grain caused by insufficient threshing c) Losses of grain caused by insufficient separation d) Losses of grain over the sieve pan |

|

a) Losses of the grain over the cutter bar |

1. Adjust reel tine angling to suit crop conditions 2. Adjust reel speed to match ground speed 3. In crops with hanging grain heads fit a grain lifter to every second cutterbar finger 4. Adjust dividers to avoid built up of material 5. Adjust main table auger position to match crop condition 6. Adjust reel forward or backward as necessary 7. Have slip clutches of reel reset to correct torque |

|

b) Losses caused by insufficient threshing |

1. Have damaged or worn threshing during repaired 2. Adjust drum speed to crop conditions 3. Adjust concave to drum clearance to crop conditions. 4. Correct basic adjustment of concave 5. Adjust relative position of concave entrance and concave exit to match crop conditions 6. Adjust cutterbar to ensure even crop feed 7. Reduce ground speed 8. Crop not ready for threshing |

|

c) Losses of grain caused by insufficient separation |

1. Provide for even crop feed to the threshing parts 2. Try to pick up less green stuff 3. Severe straw conditions clog up the cage sieves. Clean it through the inspection doors |

|

d) Losses of grain over the sieves |

1. Avoid heavy build up of material 2. Increase air blast to meet crop conditions 3. Set cutterbar high enough to minimize green stuff entering the combine 4. Decrease drum speed when sort straw overloads the sieve pan, possible open concave at the rear 5. Adjust tension of sieve pan drive belts 6. Adjust rear end of upper frogmouth sieve wider open 7. Check and have speed of main drive shaft adjusted to 1140±5 rpm if necessary 8. Clean upper and lower sieves and preparing floor 9. Adjust frogmouth sieve gaps wider open and increase wind blast 10. Check fan speed pulleys for smooth operations 11. Avoid excessive amount of grain in the returns 12. Reduce ground speed |

Transmission system:

Brake:

|

A. path of brake pedal too long due to worn out or not properly adjusted brake linings |

1. Replace the lining or adjust the brakes

|

|

B. Brake pedal does not return effectively because tension spring has lost its tension or elongated. |

1. Replace the tension spring

|

|

C. Insufficient breaking action due to 1. Brake lining contaminated with grease or oil 2. Water may have penetrated in the brake housing 3. Brake assembly bolts are loose.

|

1. Replace the brake lining

2. To vaporize the water apply brakes several times 3. Tighten the bolts |

|

D. Pulling towards one side due to brake adjustment of one side, either too tight or too loose. One side lining contaminated with grease or oil |

1. Readjust the brakes equally |

Hydraulic system: A hydraulic cylinder lifts the cutter bar too slow due to

|

Problem |

Remedy |

|

1. Hydraulic pump belt loose 2. Improper grade of oil 3. Leakage in the system 4. Blockage in the system 5. Air in the system |

1. Set to proper tension 2. Use proper grade oil 3. Set it right 4. Correct it 5. Bleed it |

General

A. Premature belt wearing / belt flickering/ jockey pulley support breaking due to

|

Problem |

Remedy |

|

1. Wrong alignment 2. Fouling of belt 3. Improper spring tension 4. Wrong pulleys fitted |

1. Set right alignment 2. Correct fouling 3. Set the specified tension 4. Put right pulleys |

B. Premature wearing of chains and sprockets’ due to

|

Problem |

Remedy |

|

1. Alignment not OK 2. Chain loose |

1. Set it right 2. Tighten the chain |

6. Maintenance of harvesting equipment:

a) Maintenance of combine harvester:

Maintenance at proper time and with proper techniques increases the workability, quality of work and life of machine. Hence during the operation the maintenance should be undertaken as per maintenance schedule given below in order to cut-down break downs.

Before starting operation:

Preparation of the combine harvester before starting the harvesting season should be done as follows:

I. Clean the diesel tank and top up with clean diesel

2. Change all diesel filter elements.

3. Change the engine oil and oil filter.

4. Check and reset tappet clearance.

5. Check the injection pressure and spray of the injectors.

6. Change air cleaner oil, clean air cleaner bowl and refill it with recommended grade of oil.

7. Change hydraulic oil and top-up with the recommended grade of oil.

8. Change sieves and straw walker.

9. Check battery for its voltage, electrolyte level and gravity. If required add only distilled water to make up the electrolyte level.

10. Lubricate all greasing points.

11. Check oil in transmission and hydraulic system.

12. Check flat belts, V-belts and roller chains for proper tension.

13. Check water level in the radiator. Use only fresh and clean water.

14. Check tyre pressure and reset the tyre inflation (front tyre: 0.18 to 0.19 MPa and rear tyre0.25 to 0.28 MPa)

15. Check~ all nuts and bolts for their proper torque and locking.

16. Check clearance between feeder bottom and feeder angle.

17. Check clearance between 'cutter bar pan and conveyor worm.

18. Check the clearance between threshing drum and concave at front and rear.

19. Check all electrical components for their proper functioning.

20. Start the engine and check;

(a) leakages' from diesel, hydraulic, engine oil connections and

(b) Engine oil pressure, battery charging, and rate system running.

21. Check all ball and taper roller, thrust and needle roller bearings.

22. Check the chain for broken links.

23. Check welding joints and broken components for replacement. Check an shaft for any crack, bend or undersize/loose bearing surface.

8 Hours Maintenance:

Following jobs should be completed after every eight hours run of combine harvester.

I. Grease as per greasing schedule.

2. Clean pre cleaner of air cleaner.

3. Check air cleaner oil, ifit is contaminated, clean the bowl and oil of the air cleaner

4. Check water in the radiator.

5. Check for leakage and rectify if any defect.

Daily Maintenance:

1. Clean the machine and engine from dust and straw particles.

2. Complete 8 hrs maintenance and it is essential to clean the air cleaner bowl and to change the oil.

3. Check engine oil and top up if required.

4. Check proper tension of V-belts, flat belts and roller chains, adjust if required.

5. Check tire pressure and reset if required.

6. Top up diesel in the diesel tank, always use clean and pure diesel.

7. Check the condition of knife blades and replace the damaged ones.

8. Check and tighten loose nuts and bolts.

9. Clean sieves, stone trap and straw walkers.

10. Grease as per greasing schedule.

II. Check and rectify welded joints and cracks.

12. Check oil level in the hydraulic tank and top up,if required

13. Start the engine, run the 'machine for a few minutes, then check for any leakage, battery changing, engine oil pressure, engine rpm, system running, any abnormal sound from the system.

After 50 Hours maintenance:

1. Repeat 8hrs and daily maintenance.

2. Open drain plug of fuel filter and drain dirty fuel.

3. Check fuel filter and replace if clogged.

4. Check water separator.

5. Check oil level in the F.I.Pump and top up.

6. Check oil level in the gear box and reduction, top up, if required

7. Check battery electrolyte level and top up , if required.

8. Checks vent plugs of the battery and clean.

9. Bleed the fuel system and run the engine.

10. Check engine and chassis mounting bolts.

After 150 hours maintenance

1. Perform daily and 50 hrs maintenance.

2. Start the engine for a few minutes and drain engine oil and refill with recommended grade of oil.

3. Change oil and fuel filters.

4. Change the 'water in the radiator.

5. Check and reset tappet clearance, if required.

After 300 hours maintenance

1. Perform daily 0 hrs and 150 hrs maintenance.

2. Check oil in the gear box, reduction, steering column and hydraulic tank.

3. Check injector for correct opening pressure and spray.

4. Tighten engine head bolts and nuts.

References:

Jain S. C. and Philp Grace (2003) Farm Machinery an approach. Book Pub. Standard Publisher and distributor, New Delhi

Wadhwa D.S., Dhingra H. S. &Santokh, Singh Field operation and maintenance of tractor and farm machinery (FMP-301), laboratory manual by, Department of Farm Machinery and Power Engineering, PAU Ludhiana

www.agricoop.nic.in/dacdivision/machinery1/chap5.pdf date of visit Nov12,2013