Site pages

Current course

Participants

General

Module 1. Basic Concepts, Conductive Heat Transfer...

Module 2. Convection

Module 3. Radiation

Module 4. Heat Exchangers

Module 5. Mass Transfer

Lesson-30 Numerical Problems related to heat exchanger performance

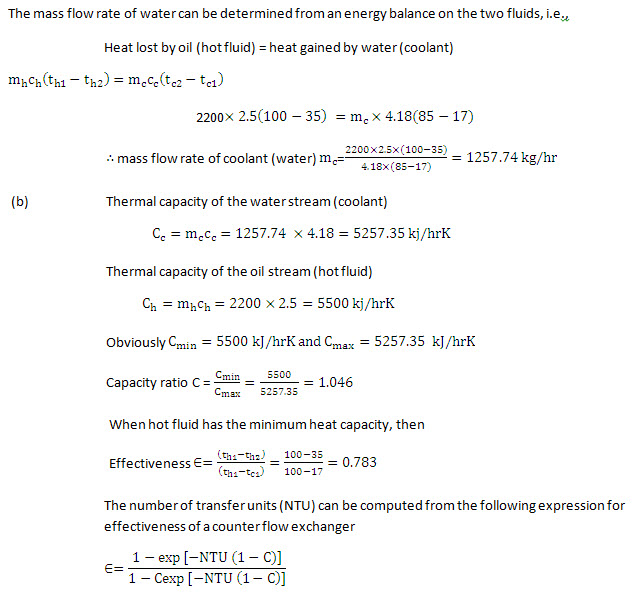

Example13.20 A counter flow heat exchanger is used to cool 2200 kg/hr of oil (cp=2.5 kJ/kgK), from 100°C to 35°C by the use of water entering at 17°C. If the overall heat transfer coefficient is expected to be 1.5 kW/m2k, make calculations for the water flow rate, the surface area required and the effectiveness of heat exchanger. Presume that the exit temperature of water is not to exceed 85°C. Use NTU-effectiveness approach.

Solution:

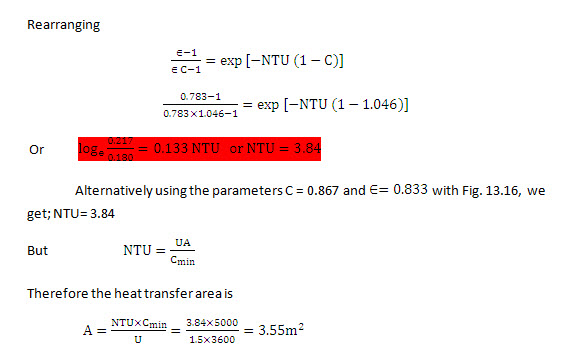

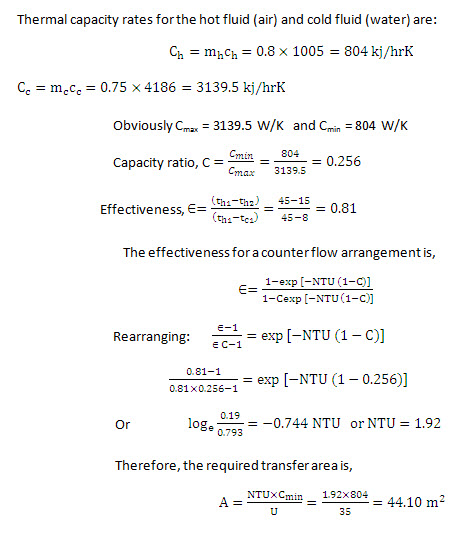

Example13.23A home air-conditioning system uses a counter flow heat exchanger to cool 0.8 kg/s of air from 45°C to 15°C. The cooling is accomplished by a stream of cooling water that enters the system with 0.5 kg/s flow rate and 8°C temperature. If the overall heat transfer coefficient is 35W/m2K, what heat exchanger area is required? If the same air flow rate is maintained while the water flow rate is reduced to half, how much will be the percentage reduction in heat transfer? Use effectiveness-NTU approach.

Solution:

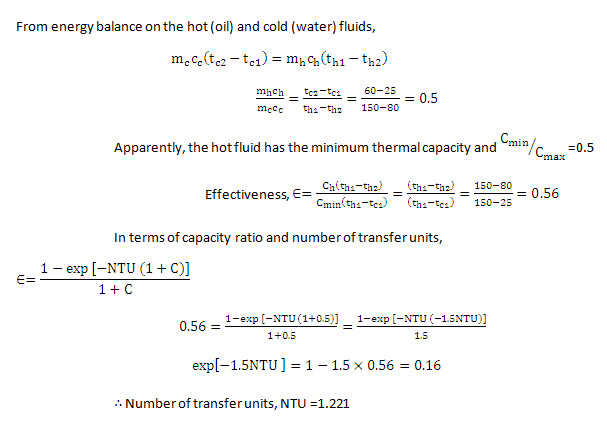

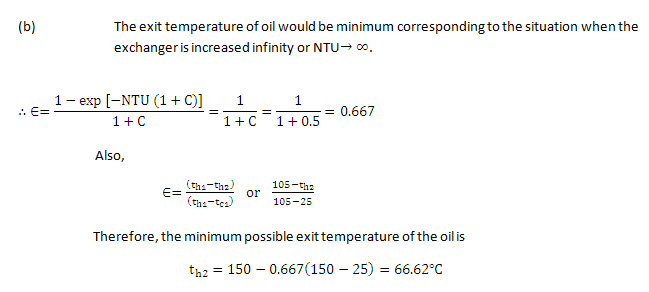

Example13.26 The Engine oil at 150°C is cooled at 80°C in a parallel flow heat exchanger by water entering at 25°C and leaving at 60°C. Estimate the exchanger effectiveness and the number of transfer units. If the fluid flow rates and the inlet conditions remain unchanged, work out the lowest temperature to which the oil may be cooled by increasing length of the exchanger.

Solution:

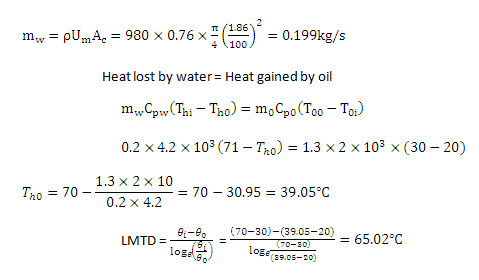

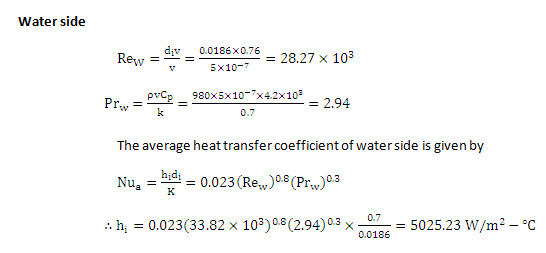

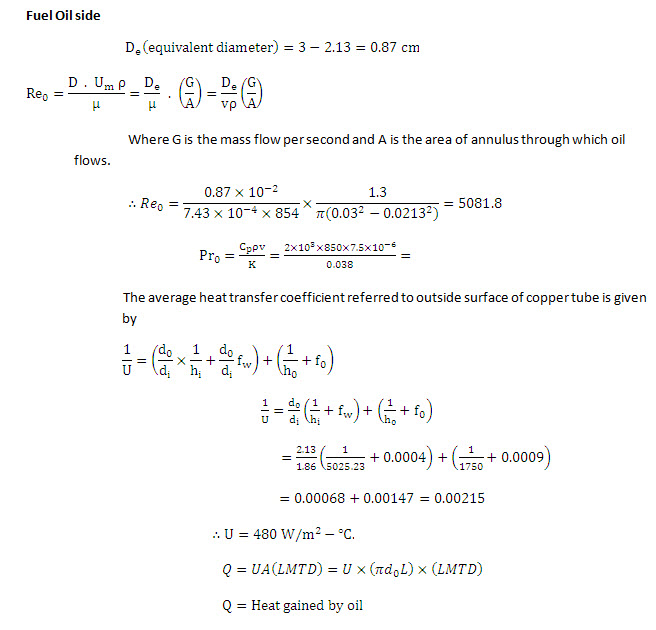

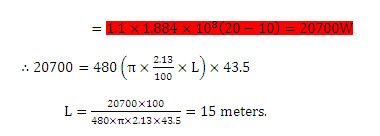

Example21.5 Fuel oil at the rate of 1.3 kg/s is heated passing through the annulus of a computer flow double pipe heat exchanger from 20°C to 30°C by using hot water available from the engine at 70°C. The water flows through a copper tube (OD=2.13 cm and ID=1.86 cm) with a velocity of 0.76 m/s. The oil passes through the annulus formed by inner copper tube and outer steel pipe (OD=3.34cm and ID=3 cm).

Fw (Fouling factor water side)=0.0004 m2 C/W

F0 (Fouling factor oil side)=0.0009 m2 C/W

Take the following properties of water and oil

|

|

Water |

Oil |

|

(kg/m3) |

980 |

850 |

|

C,(kj/kg-°C) |

4.2 |

2 |

|

K (W/m-C°) |

0.7 |

0.038 |

|

V(m2/s) |

4.2 |

7.5 |

Neglect the resistance of copper tube.

Solution:

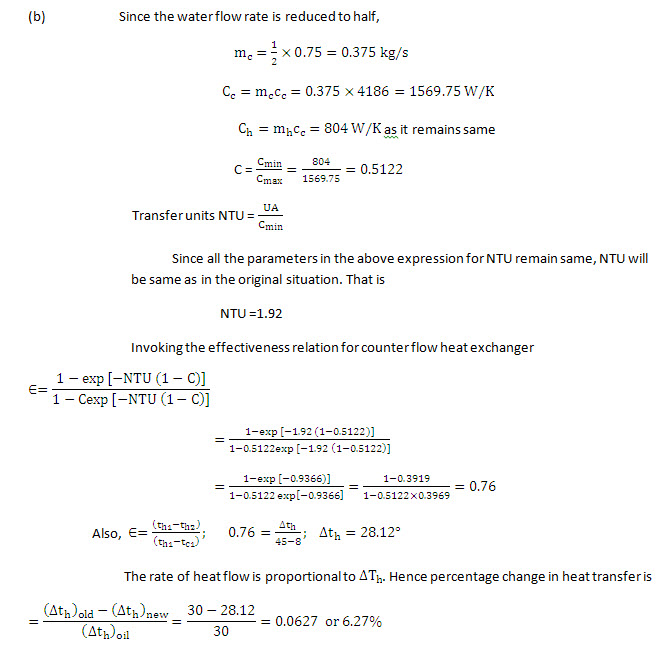

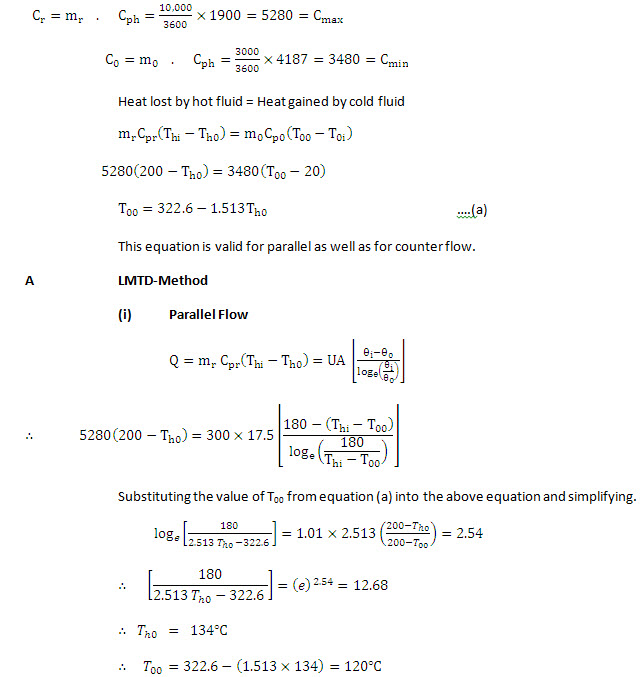

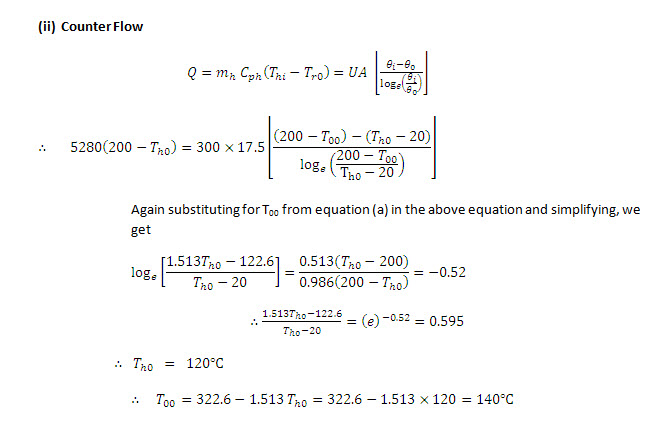

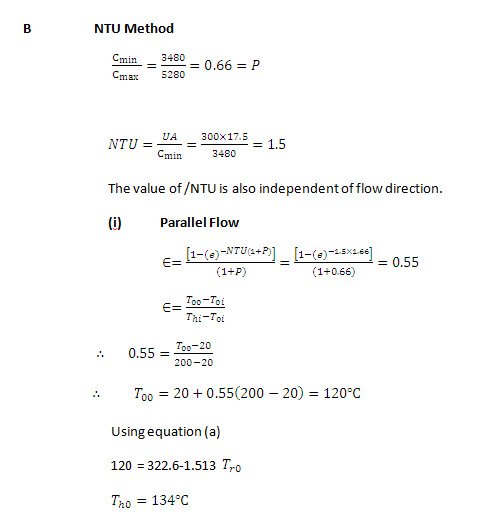

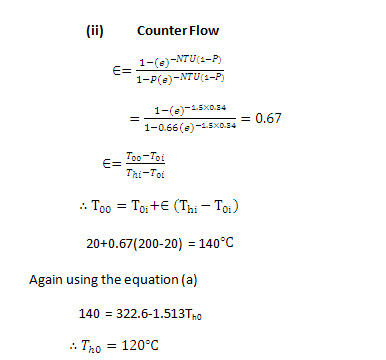

Example21.8 A heat exchanger has 17.5 m2 area available for heat transfer. It is used for cooling oil at 200°C by using water available at 20°C. The mass flow and specific heat of oil are 10000 kg/hr and 1.9 kJ/kg K and the mass flow and specific heat of water are 3000kg/hr. and 4.187 kJ/kg K. if the overall heat transfer coefficient is 300 W/m2-K, estimate the outlet temperatures of oil and water for parallel flow and counter flow arrangements (a) by using LMTD method and (b) NTU method

Solution:

Note. When NTU and () Values are known, then we can directly read the value of from the graphics instead of calculation.