Site pages

Current course

Participants

General

MODULE 1. Introduction to mechanics of tillage tools

MODULE 2. Engineering properties of soil, principl...

MODULE 3. Design of tillage tools, principles of s...

MODULE 4. Deign equation, Force analysis

MODULE 5. Application of dimensional analysis in s...

Module 6. Introduction to traction and mechanics, ...

Module 7. Traction model, traction improvement, tr...

Module 8.Soil compaction and plant growth, variabi...

LESSON 21.TRACTION MODEL

21.1. INTRODUCTION

Of the three principal ways of transmitting tractor-engine power into useful work—power takeoff, hydraulic, and drawbar—the least efficient and most used method is the drawbar.

Traction is the term applied to the driving force developed by a wheel, track, or other traction device.

Tractive efficiency (TE) is defined as the ratio of output power to the input power for a traction device. It is the measure of the efficiency with which the traction device transforms the torque acting on the axle into linear drawbar pull. Several factors lower the tractive efficiency; among these are steering, rolling resistance, slip, and friction in, and deflection of the traction device.

Net traction coefficient () is defined as the ratio of the net pull produced to the dynamic normal load on the traction device. The difference between traction efficiency and coefficient of net traction should be recognized.

Motion resistance ratio () is defined as the rolling resistance force divided by the normal load on the traction device.

21.2. TRACTION MODEL

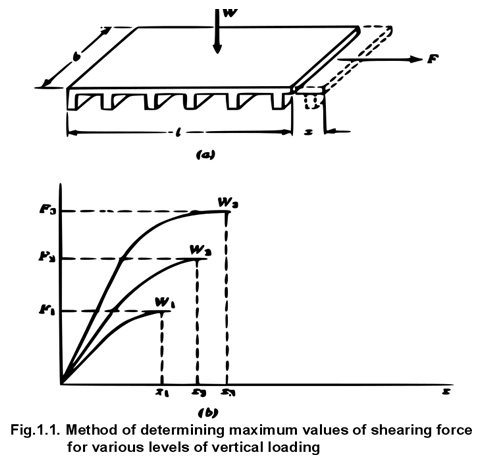

If a plate of width b and length l is equipped with lugs sufficiently long, such that an area A = bl shears off as in Fig. 1.la, we find that the force required is usually dependent upon both the normal force and the area.

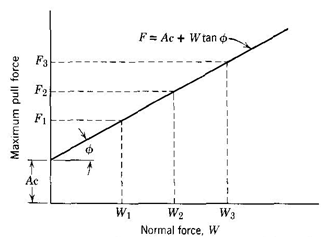

If we plot maximum values of F against W (as in Fig. 1.2), we find for soils having some cohesion that F does not approach zero as W approaches zero. If the maximum values are plotted for a soil that has both cohesion c and internal friction, the result will be similar to Fig. 1.2. The equation for such a curve is

F = Ac + W tanϕ -------------------------------------------- (1.1)

or F = A(c + p tanϕ) ------------------------------ (1.2)

where, p = W/A is the average normal soil pressure and A is the area.

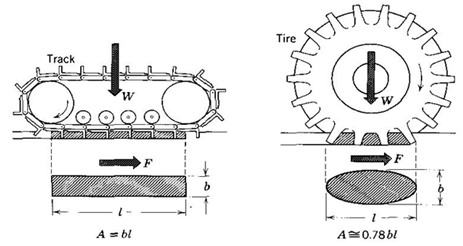

For a track

![]() ------------------------(1.3)

------------------------(1.3)

where, b is the width of the track and l is the length of the track in contact with the soil. Uniform pressure is assumed.

For a rubber tire, the "footprint" is approximately in the shape of an ellipse (Fig. 1.3) for which case,

![]() --------------------- (1.4)

--------------------- (1.4)

If we know the soil values c and ϕ, the maximum soil thrust can now be approximated by equation 1.2.

This simple model is not very useful because we seldom know c and,and p is not uniform. In addition the model does not predict the magnitude of the motion resistance force acting on the traction device.

Fig 1.2. The soil parameters c and ϕ can be determined from a plot of maximum values of the shearing force F versus the normal force W

Fig 1.3. Soil thrust from a traction member affected by both shear area and weight

21.3. WEIGHT TRANSFER

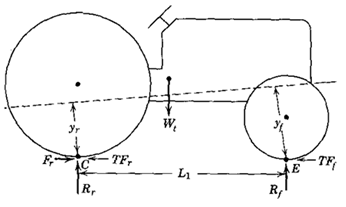

The tractive ability is affected by the vertical soil reaction against the traction wheels. Weight transfer, from drawbar pull, decreases the soil reaction against the front wheels by an amount and increases the reaction against the rear wheels by an amount ∆Rf, thus adding to the maximum drawbar pull for a two-wheel-drive tractor. The symbols in the "weight transfer" equations are defined in Fig. 1.4.

![]() ------------------------------------------------ (1.5)

------------------------------------------------ (1.5)

![]() ------------------------------------------------ (1.6)

------------------------------------------------ (1.6)

Fig. 1.4 Steady-state free-body diagram of drawbar pulland soil reactions on a tractor

Any means of increasing the rear wheel reaction will increase the traction of the rear wheel if the soil has sufficient strength and if sinkage does not limit the traction.

21.4. FOUR-WHEEL-DRIVE TRACTORS

The path or wheel track produced by the front wheels of a 4WD tractor having equal-sized tires usually increases the soil strength for the rear tires. The stronger soil increases the traction and also decreases the rolling resistance for the rear wheels. As a result, both the net tractive coefficient and the tractive efficiency should be greater for a 4WD tractor than a 2WD tractor when operating on soft compactible soil.

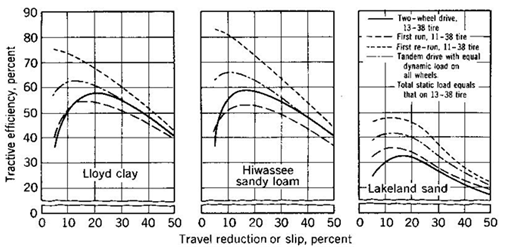

Reed et. al. (1959) found (Fig. 1.5) that at 10% slip on Hiwassee sandy loam soil, the tractive efficiency of the 2WD was 56%, while that of the tandem drive was 66%.

Fig 1.5. Power efficiency and travel plan reductions for two-wheel and tandem four-wheel-drive tractors. Data are for tractors of equal weight with the dynamic load equally distributed on all wheels for the tandem drive. (from I.F.Reed, A.W.Cooper, and c.A.Reeves, Trans. of ASAE, Vol. 2. No.1, 1959)

Dwyer and Pearson (1975) also found that the traction of the rear wheels (second pass) was greater, especially in soft soil. Dwyer found that the rolling resistance of the second pass was less than on the first pass. The average maximum drawbar power of a 4WD tractor with equal-sized wheels in all field conditions was 14% greater than that of a 2WD tractor. A 4WD tractor with unequal-sized wheels had 7% greater drawbar power than did the 2WD tractor.

21.5. TREAD DESIGN

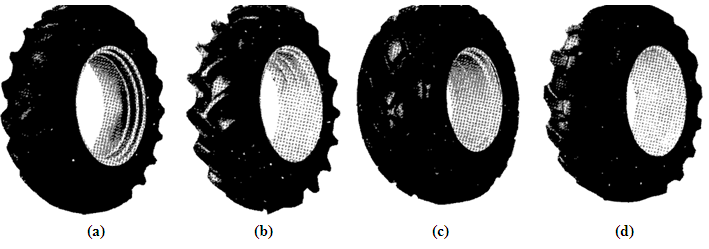

The design of the tread on tires has been the subject of much debate because the performance of one tread compared to other treads is affected by the traction conditions and the performance criteria being used. Some of the |available tire treads are illustrated in Figs. 1.6 and 1.7.

Fig. 1.6. Common North American types of tractor tire treads, (a) R-l or general

purpose tread; (b) R-2 or deep lug cane and rice tread; (c) R-3 or flotation;

and (d) R-4 or industrial lug.

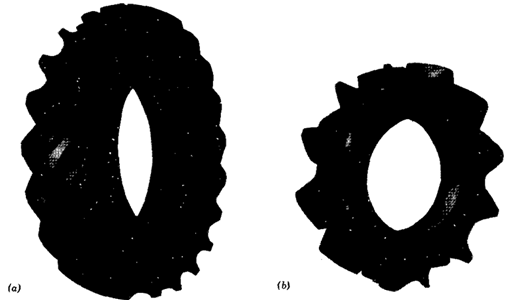

Fig. 1.7. (a) European-style tire with wider lugs for improved road wear. (Courtesy

The Goodyear Tire and Rubber Co.) (b) Japanese style tire for rice soil

conditions.

21.6. TRACTION CONDITIONS AFFECTING PERFORMANCE

Some traction conditions that affect performance are:

Soil parameters (physical properties)

Presence of crop residues and cover crops

Direction of loading of tire (e.g., hillside use)

Load carried by tire

Tire pressure (deflection ratio = deflection/tire section height)

The decision as to which tire tread performs best is also dependent on the criteria being used. Some of the criteria are:

Tractive efficiency

Net tractive coefficient

Tire life

Soil compaction