Site pages

Current course

Participants

General

MODULE 1. Introduction to mechanics of tillage tools

MODULE 2. Engineering properties of soil, principl...

MODULE 3. Design of tillage tools, principles of s...

MODULE 4. Deign equation, Force analysis

MODULE 5. Application of dimensional analysis in s...

Module 6. Introduction to traction and mechanics, ...

Module 7. Traction model, traction improvement, tr...

Module 8.Soil compaction and plant growth, variabi...

LESSON 24.TIRES FOR AGRICULTURAL TRACTORS

24.1. TIRES

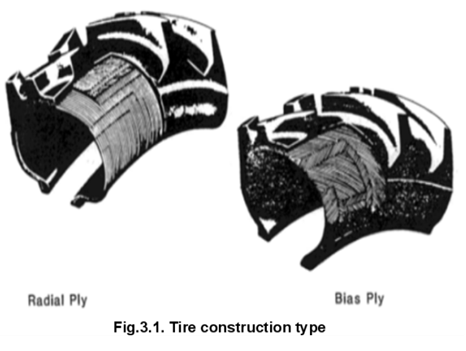

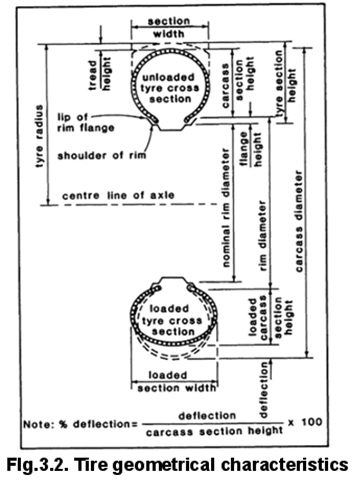

A tire forms a torus of a complex flexible reinforced composite material surrounding a steel hub and filled up with air under pressure. It has more or less expanded ribs on the rolling tread. The different types of torus shapes and construction are selected according to the tire application. In general, a tire is characterized by the tire construction type, (figure 3.1), mounting data, ply rating and other dimensions such as that shown in figure 3.2.

24.2. TIRE DEVELOPMENT

The steel-wheeled tractor was replaced by vehicles fitted with pneumatic tires in the 1920s and 1930s. Harvey Firestone (1868-1938) was instrumental in developing reinforced, "low-pressure" tires that were suitable for agricultural field work. World War II resulted in shortages of natural rubber previously used for tire production. This accelerated the research and development of synthetic rubbers such as styrene and latex. The synthetic rubbers produced had better wear-resistant properties than the original rubber tires. Synthetic rubbers that are commonly used today include polyurethane, neoprene, polybutandiene, and butyl. Natural rubber may still be used for some specialized applications.

24.3. TIRE FUNCTION

The agricultural tire must perform the following functions:

support the vehicle and associated loads at some low level of ground pressure,

absorb shock loads and cushion the vehicle against minor surface irregularities,

provide traction (and braking), .

provide for steering and directional stability,

resist the abrasive action of the various surfaces on which it is expected to operate.

24.4. CATEGORIES OF TIRE APPLICATIONS

The type of application (of tyres as traction elements) can be divided into the following four broad categories, each of which is comparatively unique.

1.In the construction field, as typified dam, waterway and highway projects which require movement of large quantities of earth and rock. In this type of service, speeds as high as 40 to 80 km h-1, length of haul to 16 km, and size of loads and equipment to 75 m3 capacity are generally expected.

2.In the logging, mining and petroleum industries – heavier units such asmobile cranes and self contained pumps and power plants, are used. This demands tire types with high floatation characteristics and load carrying capacities.

3.In military operations. In this field the various types of tired vehicles are expected to operate over a great variety of surfaces in cross-country transport. Reliability is of particular importance.

4.In general transportation into newly developed areas without adequate highways or railways – such vehicles must have floatation and mobility capability under heavy loads, without the need for extensive preparation and maintenance of roads or tracks.

24.5. TIRE SIZES AND TYPES

The growth of off-road operations has brought about a great diversification in tires to meet all service requirements.

1. Number of sizes. Tires have become larger both in cross-section and in rim diameter. Larger tires permit higher loads per tire without sacrificing floatation.

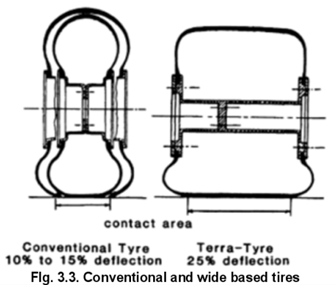

2. Conventional vs wide base. Two types of tires now exist namely, conventional and wide base. Figure 3.3 illustrates the differences between these two types of tires. Without changing the rim diameter or tire overall diameter, the cross-section width can be increased by using a wider rim. With the same tire loading, inflation pressures on the wide base tire can be reduced. The wider cross-section gives improved traction and floatation and the lower unit ground pressure can improve the resistance to damage from stones and other objects.

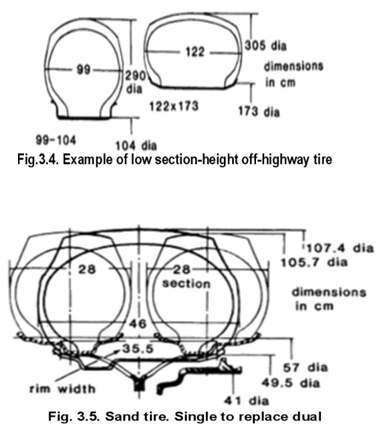

3. Low section-height tires. The wide base principle can be extended into low section-height tires. Figure 3.4 compares two tire types. The low section-height shape makes possible a wider cross-section for improved floatation without increasing overall diameter or tire weight, as would have been necessary if conventional tire shapes had been maintained.

4. Single vs dual. Another application of low-section height principle is in the use of larger simple tires to replace dual tires (figure 3.5). Although the change from dual tires to on large single tire reduces total ground contact area, experience has shown that floatation and mobility are improved without reduction in total oad carrying capacity.

5. Tread pattern. All off highway operations do not need the same degree of traction. As a result, separate tread designs are used for different degrees of tractive effort.

24.6. TREAD

The important variables in relation to the tyres include:

(i) size (diameter and width) which determines their tractive capacity and rolling resistance.

(ii) strength, expressed in terms of ply rating, which in turn determines the pressure that can be used and hence the weight that the tire can carry; this in turn also determines the tractive capacity and the rolling resistance.

(iii) tread pattern which, together with the surface characteristics, determines the engagement and / or contact with the surface.

The losses in power at the wheel / surface interface are often great, particularly on soft surfaces (ie, their efficiency is low), hence the power available at the tractor drawbar may be much less than the power of the engine. Hence the choice of the tires and the weight on them is crucial in determining the overall performance of the tractor.

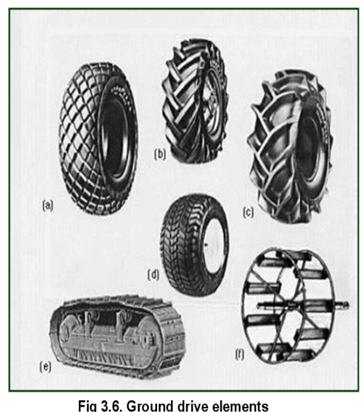

Various types of wheels and / or tyres may be used on the tractor, depending mainly on the surface on which it is working. For the following conditions, the tyres or wheels indicated are recommended as shown in Figure 3.6.

|

|

Surface |

Tread form |

|

(a) |

Hard surfaces such as roads |

Large area, shallow tread with ‘high’ pressure |

|

(b) |

Normal agricultural work, dry soil |

Heavy, intermediate depth tread |

|

(c) |

Soft, wet agricultural soils |

Deep tread |

|

(d) |

Lawns, low sinkage is required |

Wide, low pressure |

|

(e) |

Dry soil, heavy loads as in earth moving |

Tracks, as on a “crawler” tractor |

|

(f) |

Saturated puddle soils |

Metal cage, with angled lugs, alone or as extensions to normal tires |