Site pages

Current course

Participants

General

MODULE 1. Introduction to mechanics of tillage tools

MODULE 2. Engineering properties of soil, principl...

MODULE 3. Design of tillage tools, principles of s...

MODULE 4. Deign equation, Force analysis

MODULE 5. Application of dimensional analysis in s...

Module 6. Introduction to traction and mechanics, ...

Module 7. Traction model, traction improvement, tr...

Module 8.Soil compaction and plant growth, variabi...

LESSON 23. CONE INDEX AND TIRE BASICS

Cone Index: Cone index is used as the measure of soil strength in the traction equations. Cone index is the average force per unit base area required to force a cone-shaped probe into soil at a steady rate. The design and use of the cone penetrometer is discussed in ASAE R 313.1. (Agricultural Engineers Yearbook, 1977).

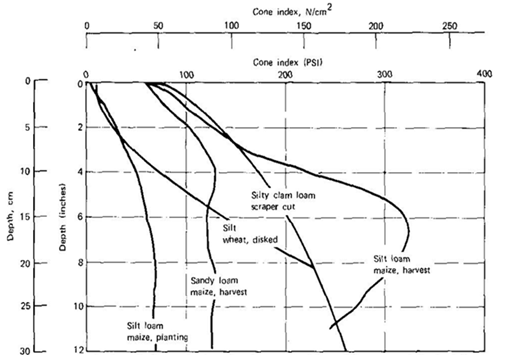

Fig. 2.4. Typical cone index-depth curves (Wismer and Luth, 1974)

Cone index characteristically varies with depth of penetration (figure 2.4). Thus the question arises as to what cone index value should be used. For the traction equations, the 0 to 6 in. (15 cm) average cone index has produced the best correlations for machines with tire sinkages of less than 3 in. (7.5 cm). However, if the tire sinkage is greater than this value the cone index should be averaged over the 6-in. (15 cm) layer, which includes the maximum sinkage of the tire. In general, cone index should be measured before the soil is subjected to wheel traffic.

Highly compactible soils, such as freshly tilled soils, present a special problem in predicting tractive performance. The soil tends to compact and increase in strength under heavy tire loads. Cone index measured after traffic may be several times the value measured before traffic. Best results to date have been accomplished by using after-traffic cone index values in the developed equations for highly compactible soils. No satisfactory method has been devised for predicting after-traffic cone index from before-traffic measurements.

23.1 Tire Size, Load, and Air Pressure Relationship

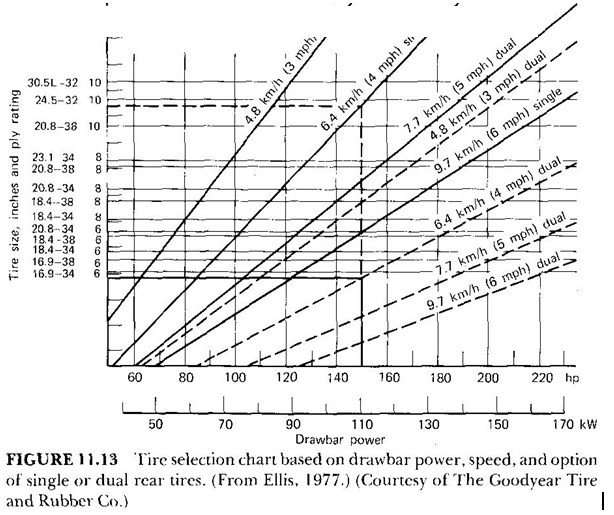

The tire companies, through the RMA (Rubber Manufacturers Association), have determined load and torque limits for each tire. This information (see Appendix) is published in the form of standards by SAE (J709d) and by ASAE (S295.1). Using this information, it is possible to select the minimum size tire for a given tractor load condition. Such a tire will be correctly sized for the vertical load and torque. However, it may be too small for the soil conditions. Ellis (1977) has simplified the problem by using the tractor power and operating speed as a basis for selecting the proper tire. From this graph (see Fig. 11.13), one can also select the proper combination of dual tires. Note that the use of dual tires does not double the power that can be transmitted by the tires.

Because a tractor may be used in a variety of soil conditions and loads, the manufacturer will have several sizes, treads, and ply ratings available for each tractor. One manufacturer of a popular 2WD tractor with 105 kW advertises 10 different tires available plus 5 different dual arrangements for the rear driving wheels. The same tractor also has 6 different front tire sizes available.

23.2 Radial-Ply Construction

The advantage of using radial-ply tractor tires as compared to bias-ply tires is not as pronounced for tractors as for highway vehicles where the increase in life (mileage) and the decrease in fuel consumption justify the extra cost. Radial-ply tires have been used to a greater degree on tractors in Europe than in North America, possibly because European tractors are used more for highway transportation. In addition, the cost of fuel is much greater.

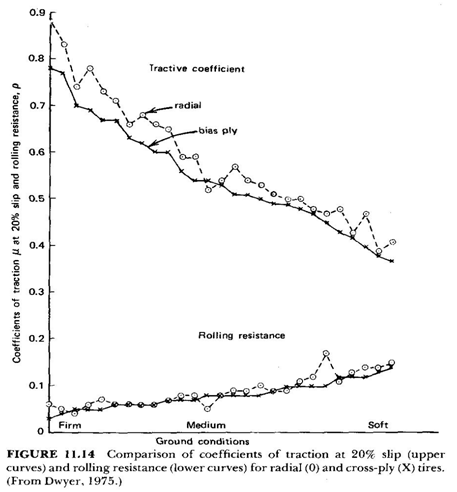

The advantage of the radial-ply tractor tire in significantly improving the coefficient of traction under most all conditions is shown in Fig. 11.14 from a study by Dwyer (1975). Taylor et al. (1976), at the National Tillage Machinery Laboratory, found a smaller advantage for the radial-ply tire. Taylor found that on five of seven soils, the coefficient of net traction at 15% slip increased 6% to 18%. However, the tractive efficiency of the radial-ply tire was only slightly higher. On soft soils, there was no advantage for the radial-ply tire.

23.3 Effect of Lug Spacing

A study was made by Taylor (1974) on the effect of lug spacing on 11.0-38 (279-965 mm) tires. The number of lugs per side on the five tires tested was 20, 23, 26, 29, and 32, which gave a pitch (in millimeters) of 238, 207, 178, 164, and 148. Taylor found (see Fig. 11.15) that when the tires were tested on sod the maximum pull occurred when using the 23-Iug tire. On the other soil conditions tested, lug spacing had little effect.