Site pages

Current course

Participants

General

Module 1. Introduction to Theory of Machine

Module 2. Planar Mechanism

Module 3. Velocity and Acceleration Analysis

15 March - 21 March

22 March - 28 March

29 March - 4 April

5 April - 11 April

12 April - 18 April

19 April - 25 April

26 April - 2 May

Lesson 25.

25.1 VEE-BELT DRIVES

V- Belts are used where there is constraint of available space and designer wants to have compact layout of the drive system. The operation of such type of belt drives is smooth and noiseless. The life of V-belts is quite long if their contact with water and chemicals is avoided. The operating speed of V- belts is generally between 5 m/s to 50 m/s.

25.2 CHAIN DRIVES

Chain is a series of connected links which are typically made of metal and is used where no slippage is required. A chain may consist of two or more links. The chains on the basis of their use is classified into following three groups.

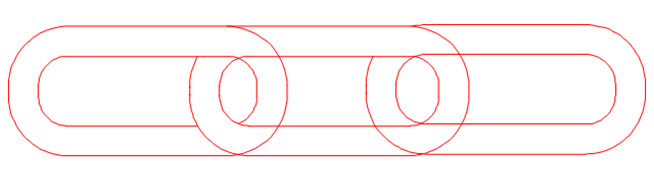

1) Hoisting and hauling chains: These chains are used for lifting, lowering, pulling or dragging operations. They are generally of oval or square shape. Figure 5.9 shows the diagrammatic representation of the same

Fig 5.9 Hoisting and Hauling chains

2) Conveyor chains

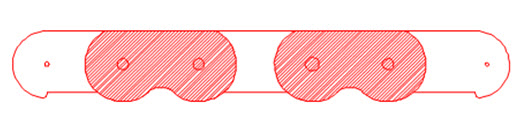

These chains are made from malleable cast iron and are used for transporting material from one place to another on a conveyor system. The cross section of conveyor chain is shown in the figure 5.10

Fig 5.10 Conveyor chains

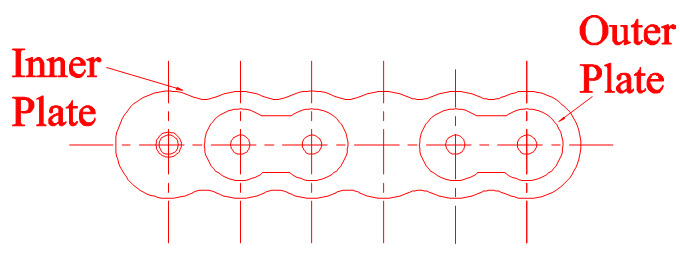

3) Power transmitting chains: As the name suggests these chains are used for power transmission. They may be of categorized as block chains, bush roller chains and inverted tooth or silent chains

Fig 5.11 Power transmission chains