Site pages

Current course

Participants

General

Module 1. Hydraulic Basics

Module 2. Hydraulic Systems

MODULE 3.

MODULE 4.

MODULE 5.

MODULE 6.

MODULE 7.

MODULE 8.

LESSON 11. Filtering Elements

11.1 Introduction

Filtration is an important part of any hydraulic system or machinery which provides the safety of a system or machinery. It also maintains the right condition of fluid circulating in the circuit. Contamination of the fluid may result in wear in the moving parts, corrosion, reduced performance, and also clogging. Therefore filtration is needed to remove the solid contaminants from the circulating fluid. Usually filter work on the basis that it traps the particles in the small holes or pores. It allows the fluid to pass through it but the particles of certain size get trapped in the filters.

11.2 Types of Filter Elements

There are mainly two types of filter elements used in hydraulic systems – surface filters and depth filters.

11.2.1 Surface Filters Element

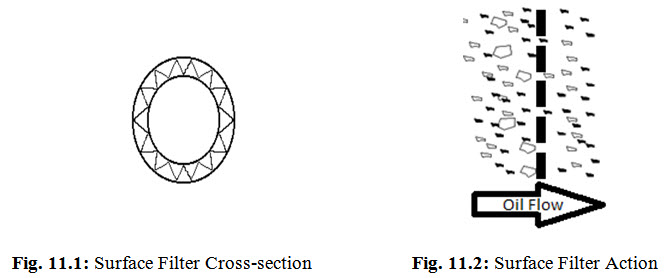

Surface filters are simple screens which are used to clean oil passing through their pores. These are normally made with thin sheets which are folded into many sections and then turned into a multi-pointed star shape as shown in Fig. 11.1. This increases the surface area for the fluid to be entered into it.By doing so the space required for the filter is reduced and this element is fitted into a bowl. The thin sheet is provided with number of pores of required size, which traps the solid contaminant when the oil is passed through it as shown in Fig. 11.2. Surface filters are usually made of woven steel wire, woven nylon fibre and cellular/paper.

11.2.2 Depth Filter Element

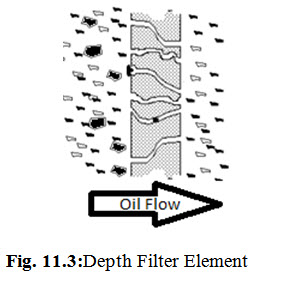

Depth filters are thick walled filter elements through which oil is passed and undesirable foreign particles are trapped in the filter. Depth type filter elements consist of hollow cylinder and its walls are made up of thick layer of cellulose. These may also be made up of multi-layered fabric, compressed fabric, plastic, felt or metallic fibre. The fluid enters from the casing and flows through the element in the hollow space in the cylinder and then cleaned fluid is discharged. In this type of element coarse particles are separated at the inlet surface whereas, finer particles are separated within the material of element. These filters will have higher capacity of dirt retention for the same area cross-section.

11.3 Comparison of Surface and Depth Filters

Depth-type filters capture particles and contaminant through the total thickness of the medium, while in surface filters particles are blocked on the surface of the filter.

Surface filters are best for filtering sediment of similar-sized particles. If all particles are say five micron, a 5-micron surface filter works best because it has more surface area than depth filters. Compared with surface filters, depth filters have a limited surface area, but they have the advantage of depth.