Site pages

Current course

Participants

General

Module 1. Hydraulic Basics

Module 2. Hydraulic Systems

MODULE 3.

MODULE 4.

MODULE 5.

MODULE 6.

MODULE 7.

MODULE 8.

LESSON 12. Filtering Materials

12.1 Introduction

Filtration may be defined as the removal of solid particles from a liquid or gaseous stream by means of a porous medium. There are numerous types of filtering material available for filtration. Filtering material may be mechanical or absorbent. Mechanical filters are relatively coarse and utilize fine wire mesh. Mechanical filters can usually be removed, cleaned and refitted for use. Absorbent filters are based on porous materials such as paper, cotton or cellulose. Filtration size in an absorbent filter can be very small as filtration is done by pores in the material.

12.2 Types of Filtering Material

There are different materials used for making filter elements are (i) Woven steel wire (ii) Woven nylon fibre and (iii) Cellulose or paper

12.2.1 Woven Steel Wire Type Material

This type of material consists of woven steel wire which may be stainless steel or epoxy based wire mesh available in different sizes which can filter from 150 µm to 40 µm of particle size. These type of materials are normally used for trapping large and harsh particulate.

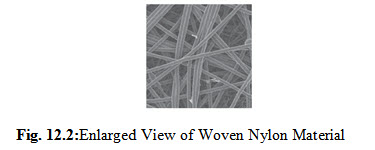

12.2.2 Woven Nylon Material

These are the nylon or synthetic fibres, which are smooth, rounded and provide less resistance to flow.Its uniform shape and size provide the smooth flow of fluid through the mat, which gives better filtration effectiveness in specific contaminants.

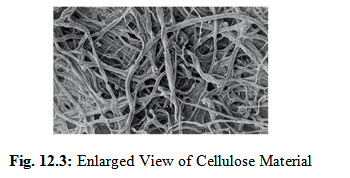

12.2.3 Cellulose typeMaterial

It is basically wood fibre having microscopic size. The fibres are held together by resin. These fibres are irregular in size and also in shape. It offers smaller pores in the material, which causes more resistance to the flow of fluid. But cellulose material provides greater effectiveness of filtration of hydraulic or other petroleum fluids

12.3 Filtration Test

Generally multi-pass test is carried out to evaluate the filter element performance.Fluid is circulated through the test circuit under controlled conditions, which indicates the following element performance characteristics:

Dirt holding capacity

Filtration efficiency as beta ratio

12.3.1 Beta Ratio (β)

It can be defined as the measure of filter element particle capturing efficiency. It is performance indicator of a filter element. Beta ratio is the ratio of particles larger than a given size counted upstream and downstreamof the test filter in a multi-pass test. Therefore it is a dimensionless number which gives degree of separation.

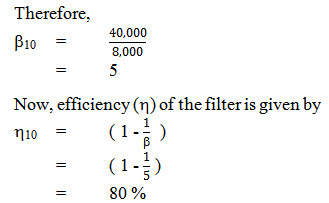

Example: In a multi-pass filter test 40,000 particles of 10 mm and larger size were counted upstream and 8,000 particles in the same range were counted downstream of the test filter. Find the beta ratio of the filter.

Solution: Given,

Threshold size of particles, x = 10 micron

Number of particles upstream, Nu = 40,000

Number of particles downstream, Nd = 8,000

Beta ratio of the filter is calculated as: ![]()

12.4 Element Indicator

The element indicator is the indicating device which gives the signals when the element is loaded to the point that it should be cleaned or replaced. The indicator may be connected mechanically to the bypass valve. But sometimesthere may be an independent differential-pressure sensing device type of an arrangement is there which gives visual or electrical signals or both.