Site pages

Current course

Participants

General

Module 1. Hydraulic Basics

Module 2. Hydraulic Systems

MODULE 3.

MODULE 4.

MODULE 5.

MODULE 6.

MODULE 7.

MODULE 8.

LESSON 13. Hydraulic Accumulators

13.1 Introduction

Accumulators are the devices used in the hydraulic systems which store hydraulic energy in the form of fluid pressure and then provide this energy back to the system when it is required in the system. Accumulators store the energy when hydraulic system pressure exceeds a threshold value and provide hydraulic energy when the system pressure falls below the threshold value. In many respects it resembles the operation of a capacitor in an electronic power supply.

13.2 Accumulator Functions

An accumulator usually performs the following functions:

It provides a reserve of power and supply oil for high transient flow demands

It provides sufficient power to complete one or more cycles of operation of the equipment when pump does not work

It helps to reduce pump ripple

It acts as a hydraulic shock absorber

It may be used as a primary power source for small hydraulic systems

Most hydraulic systems use an accumulator to dampen pressure transients in the system.The pressure transients result from pump ripple, opening/closing of valves, and so on. In some of the hydraulic systems accumulators are not being utilised, other design considerations are considered. The selection and design characteristics of accumulators will vary with the applications of accumulator in the system. A few of selection considerations are:

The size and mass of unit

Operating temperature range

Operation to be performed by the unit

Quantity of energy to be stored by the system

13.3 Types of Accumulators

Accumulators can be classified as dead-weight type,spring-loaded type and hydro-pneumatic type. The most commonly used accumulators in the industry are hydro-pneumatic type. They use a gas for storing oil under pressure. Dry nitrogen is used as the gas. Compressed air is not used to avoid air-oil vapour explosion. Following types of hydro-pneumatic accumulators are used in hydraulic circuits:

Bladder type accumulator

Diaphragm bladder type accumulator

Piston type accumulator

Metal bellows type accumulator

13.3.1 Bag or Bladder Type Accumulator

A bladder type accumulator consists of a metal shell,usually made of steel, attached to the fluid pipe or tube through a fluid port. The shell contains a elastomeric bladder in which gas can be filled through a valve located on the top of shell.A bladder type accumulator is shown in Fig. 13.1. The bladder is usually charged with nitrogen gas to a nominal pressure when the pumps are not operating. When the pressure in the pipe exceeds system pressure, oil flows into the accumulator against the gas pressure. When the bag is fully compressed, the nitrogen pressure and the hydraulic pressure are equal. As system pressure drops the bag expands, forcing fluid from the accumulator into the system. As the bag expands, pressure in the bag decreases. The bag will continue to expand until the bag pressure equals the hydraulic pressure. The maximum flow rate of the accumulator can be controlled by the opening area of the orifice and the pressure difference across the opening.The main advantages of this type of accumulator are fast response and low hysteresis. The bag type of accumulator is the best choice for pressure pulsation damping and is also reliable in service. Gas accumulators are generally larger than the other type of accumulators.

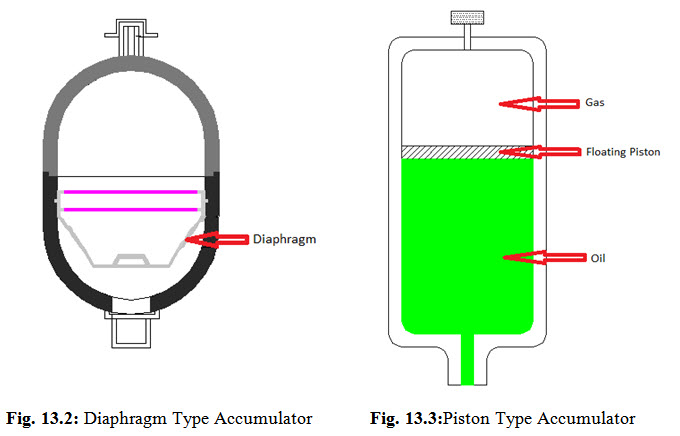

13.3.2 Diaphragm Accumulator

A diaphragm accumulator consists of a pressure vessel in two parts usually in the form of two hemispheres joined together. The two parts are separated by a flexible rubber diaphragm. A diaphragm type accumulator is shown in Fig. 13.2.This type of accumulator is similar to bag type of accumulator except the diaphragm which is used to separate the gas and oil in place of a bag or bladder to store the gas. This reduces the overall volume of the accumulator. The behaviour characteristics of a diaphragm accumulator are similar toa bag accumulator.

13.3.3 Piston Type Accumulator

Fluids are practically incompressible and hence cannot store pressure energy. The compressibility of nitrogen gas is utilized this type of accumulator. A gas piston accumulator consists of a cylinder body and a moveable piston. On one side of the piston is nitrogen gas and on the other side is the hydraulic fluid and connection to the hydraulic system. A piston type accumulator is shown in Fig. 13.3. The gas section is pre-charged with nitrogen and the fluid section is connected to the hydraulic circuit so that the piston accumulator draws in fluid when the pressure in the circuit increases. When the pressure decreases, the compressed gas expands pushing the piston and stored fluid is displaced into the hydraulic circuit. A gas piston accumulator will not respond as fast as a bladder accumulator. But a piston accumulator will have better damping. Piston accumulators will generally provide higher flow rates than gas accumulators for same accumulator volumes. This is because piston accumulators can accommodate higher pressure ratios (maximumsystem pressure to precharge pressure) in the range 10 to 1, as compared with bladderaccumulator ratios of 4 to 1. The disadvantages of piston accumulators are that they have a lower response time than bladderand will have hysteresis.

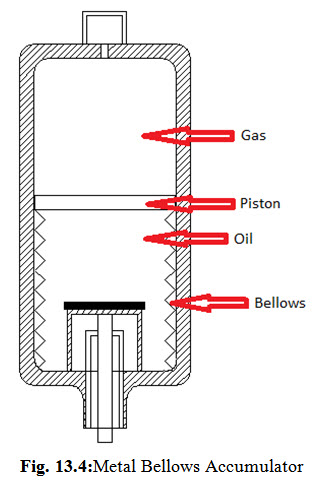

13.3.4 Metal Bellow Accumulator

A metal bellows accumulator consists of a pressure vessel with a metal bellows assembly separating fluid and nitrogen. Metal bellows are made up of Teflon and alloys which offer better dampening quality. Metal bellows are used where a fast response time is not critical. This type of accumulator is quite reliable for the hydraulic circuits. The accumulator is similar to a piston accumulator, except a metal bellows replaces piston and piston seals. Metal bellows accumulators are slow in responding to pressure changes due to increased mass of piston and bellows. Metal bellows accumulators are reliable, have long life components and have proven service history.

13.4 Gas Accumulator Precharging

The precharge may be expressed as the pressure of the gas in the accumulator without hydraulic fluid in the fluid side. A gas accumulator is pre-charged with nitrogen gas when there is no hydraulic fluid in the accumulator to the desired pressure. The gas accumulator pre-charge is a very important parameter for accumulator performance .

13.5 Accumulator Design Considerations

The design of an accumulator is based on the following factors:

-

Accumulator Type: It includes various types of hydraulic accumulators like- bag or bladder type, diaphragm, piston, and metal bellows type. Each type has advantages and disadvantages and the specifications will also vary in each type of accumulator.

-

Accumulator Volume: Another parameter is accumulator volume or the total volume of the accumulator which includes both gas and fluid volume.

-

Nominal Hydraulic System Pressure: It is the hydraulic system pressure in the system, which will usually be the no-flow rating of the hydraulic pump

-

Minimum Hydraulic System Pressure: This is the minimum pressure that the accumulator must maintain in the hydraulic system. This parameter helps in designing of size of the accumulator.

-

Precharge Pressure: It is basically the pressure of the nitrogen in an accumulator without any hydraulic fluid in the accumulator. This pressure indicates the amount of fluid that an accumulator canhold at the system pressure and the desired minimum hydraulic system pressure.

-

Flow Rate: The required flow rate is the basic requirement which determines the size of the accumulator. The accumulator volume for hydraulic flow is given bythe product of flow rate and time required for the flow.

Flow = Q * t

Where Q = flow rate

T = time required for the flow.

-

Output Volume: It is the output volume capacity of the fluid volume of the accumulator that is capable of providing between the nominal hydraulic system pressure and the required minimum hydraulic pressure.

-

Response Time: It is the time for the accumulator to make available the required fluid volume.

-

Recharge Time: It is the time required to fully charge an accumulator from a fully drained condition.

-

Type of Fluid: Accumulator seals and elastomeric bladder/diaphragm material must be compatible with the hydraulic fluid used in the system

-

Operating Temperature: Accumulator performance should be evaluated over the expected temperature range of the nitrogen.