Site pages

Current course

Participants

General

Module 1: Fundamentals of Reservoir and Farm Ponds

Module 2: Basic Design Aspect of Reservoir and Far...

Module 3: Seepage and Stability Analysis of Reserv...

Module 4: Construction of Reservoir and Farm Ponds

Module 5: Economic Analysis of Farm Pond and Reser...

Module 6: Miscellaneous Aspects on Reservoir and F...

Lesson 18 Failure and Damages II

18.1 Causes of Earthen Dam Failure

Earth dams are less rigid and hence more susceptible to failure. Every past failure of such a dam has contributed to an increase in the knowledge of the earth dam designers. Earthen dams may fail, like other engineering structures, due to improper designs, faulty constructions, lack of maintenance, etc. The various causes leading to the failure of earth dams can be grouped as: (1) Hydraulic failures, (2) Seepage failures, and (3) Structural failures.

18.1.1Hydraulic Failures

About 40% of earth dam failures have been attributed to these causes. The failure under this category may occur due to the following reasons:

(a) By over Topping

The water may overtop the dam, if the design flood and spillway capacity are under-estimated. Therefore, sufficient freeboard should be provided as an additional safety measure.

(b) Erosion of Upstream Face

The waves developed near the top water surface due to the winds, try to notch-out the soil from the upstream face and may even, sometimes, cause the slip of the upstream slope. Upstream stone pitching or riprap should, therefore, be provided to avoid such failures.

(c) Cracking Due to Frost Action

Frost in the upper portion of the dam may cause heaving and cracking of the soil with dangerous seepage and consequent failure. An additional freeboard allowance up to a maximum of say 1.5 m should, therefore, be provided for dams in areas of low temperatures.

(d) Erosion of Downstream Face by Gully Formation

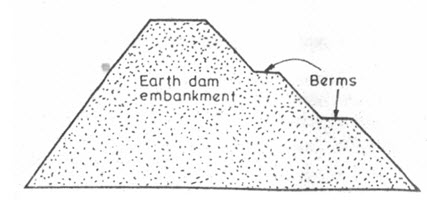

Heavy rains falling directly over the downstream face and the erosive action of the moving water, may lead to the formation of gullies on the downstream face, ultimately leading to the dam failure. This can be avoided by proper maintenance, filling the cuts from time to time especially during rainy season, by grassing the slopes and by providing proper berms at suitable heights (Fig. 18.1), so that the water has not to flow for considerable distances. The proper drainage arrangements are made for the removal of the rain water collected on the horizontal berms. Since the provision of berms ensures the collection and removal of water before it acquires high downward velocities, the consequent erosion caused by the moving water (run off) is considerably reduced.

(e) Erosion of the D/s Toe

The d/s toe of the earth dam may get eroded due to two reasons, i.e. (i) the erosion due to cross currents that may come from the spillway; and (ii) the erosion due to tail water. This erosion of the toe can be avoided by providing a downstream slope pitching or a riprap up to a height slightly above the normal tail water depth. Side walls of the spillway must be sufficient height and length, as so to prevent the possibility of the cross flow towards the earthen embankment.

Fig. 18.1. Gully erosion control in embankment.

(Source: Garg, 2011)

18.1.2 Seepage Failures

Controlled seepage or limited uniform seepage is inevitable in all earth dams, and ordinarily it does not produce any harm. However, uncontrolled or concentrated seepage through the dam body or through its foundation may lead to piping is the progressive erosion and subsequent removal of the soil grains from within the body of the dam or the foundation of the dam. Sloughing is the progressive removal of soil from the wet downstream face. More than 1/3rd of the earth dams have failed because of these reasons.

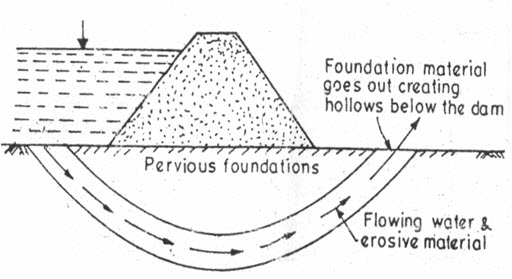

(a) Piping through Foundations

Sometimes, when highly permeable cavities or fissures or strata of coarse sand or gravel are present in the foundation of the dam, water may start seeping at huge rates through them (Fig.18.2). This concentrated flow at a high gradient may erode the soil. This leads to increase in flow of water and soil, ultimately resulting in a rush of water and soil, thereby, creating hollows below the foundation. The dam may sink down into the hollow so formed, causing its failure.

Fig. 18.2. Piping through dam foundation.

(Source: Garg, 2011)

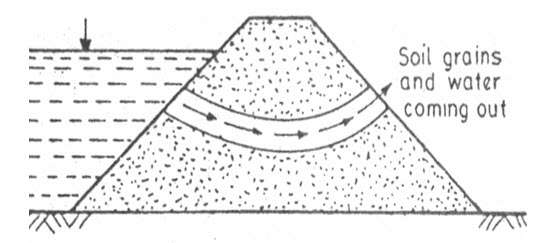

(b) Piping through Dam

When the concentrated flow channels get developed in the body of the dam, soil may be removed in the same manner as was explained in foundation piping, leading to the formation of hollows in the dam body, and subsequent subsidence of the dam (Fig. 18.3). These flow channels may develop due to faulty construction, insufficient compaction, cracks developed in embankment due to foundation settlement, shrinkage cracks, animal burrows, etc. All these causes can be removed by better construction and better maintenance of the dam embankments.

Piping through the dam body, generally get developed near the pipe conduits passing through the dam body. Contact seepage along the outer side of conduits may either develop into piping, or seepage through leaks in the conduits may develop into piping.

Fig. 18.3. Piping through dam body.

(Source: Garg, 2011)

This can be avoided by thoroughly and properly compacting the soils near the outlet conduits and by preventing the possibilities of leakage through conduits, but preventing the formation of cracks in the conduits. These cracks in the conduits are caused by differential settlement and by overloading from the embankment. When these factors are controlled, automatically, the possibility of piping due to leakage through the conduits is reduced.

(c)Sloughing of d/s Toe

The process behind the sloughing of the toe is somewhat similar to that of piping. The process of failure due to sloughing starts when the downstream too becomes saturated and get eroded, producing a small slump or miniature slide.

The miniature slide leaves a relatively steep face which becomes saturated by the seepage from the reservoir and slumps again, forming a more unstable surface. The process continues till the remaining portion of the dam is too thin to withstand the horizontal water pressure, leading to the sudden failure of the dam.

18.3 Structural Failures

About 25% of the dam failures have been attributed of structural failures. Structural failures are generally caused by shear failures, causing slides.

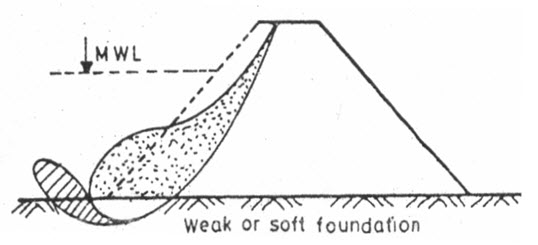

(a) Slide in Foundation

When the foundation of the earth dams are made of soft soils, such as fine silt, soft clay, etc., the entire dam may slide over the foundation. Sometimes, seams of fissured rocks, shale’s or soft clay, etc. may exist under the foundation, and the dam may slide over some of them, causing its failure. In this type of failure, the top of embankment gets cracked and subsides, the lower slope moves outward forming large mud waves near the heel (Fig. 18.4).

Excessive pore water pressure in confined seams of sand and silt, artesian pressure in abutments, or hydrostatic excess developed due to consideration of clay seams embedded between sands or silts, etc. May reduce the shear strength of the soil, until it becomes incapable of resisting the induced shear stresses, leading to the failure of the dam foundation without warning. Loose sand foundations may fail by the liquefaction or flow slides.

Fig. 18.4. Sliding due to soft or weak foundation.

(Source: Garg, 2011)

(b)Slide in Embankments

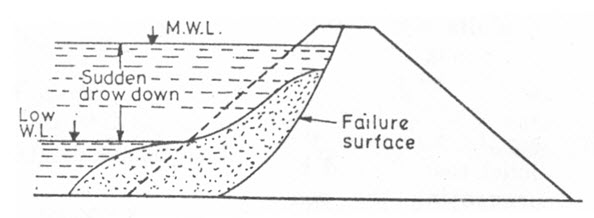

When the embankment slopes are too steep for the strength of the soil, they may slide causing dam failure. The most critical condition of the slide of the u/s slope is the sudden draw-down of water-level in the reservoir (Fig. 18.5) and the d/s slope is most likely to slide, when the reservoir is full (Fig. 18.6). The u/s slope failures seldom lead to catastrophic failures, but the d/s slope failures are very serious. These failures generally occur due to development of excessive unaccounted pore pressures which may reduce the shearing strength of the soils as explained in the previous lesson. Many embankments may fail during the process of consolidation, at the time of construction or after the construction.

Fig. 18.5. Upstream slope slide due to sudden drawdown.

(Source: Garg, 2011)

Key words: failures, seepage, piping, erosion

References

Garg, S. K. (2011). Irrigation Engineering and Hydraulic Structures. Twenty Fourth Revised Edition, Khanna Publishers, pp.773-776.

Suresh, R. (2002). Soil and Water Conservation Engineering. Fourth Edition, Standard Publishers, pp. 562-565.

Suggested Readings

http://www.eng.kufauniv.com/staff/oday/failure%20mechanisms%20for%20earth%20dams.doc

http://www.geosnet.geoengineer.org/ISGSR2007/Part2Paper1.pdf

http://des.nh.gov/organization/commissioner/pip/factsheets/db/documents/db-4.pdf

http://aitech.ac.jp/~narita/tembankmentdam1.pdf